Reactors

Reactors

At Harsha Engineers, we specialize in the design and fabrication of high-performance chemical reactors that meet the stringent demands of modern process industries. With over 25 years of experience, we manufacture a wide range of reactors — including jacketed, limpet coil, and pressure reactors — tailored to applications in the chemical, pharmaceutical, petrochemical, and food processing sectors. Each reactor is built using high-grade materials such as stainless steel (SS304/316), mild steel, and other alloys based on client requirements, ensuring resistance to corrosion, high pressure, and extreme temperatures.

Our reactors are precision-engineered for optimal mixing, heat transfer, and chemical reaction efficiency. From pilot-scale vessels to large industrial units, all our equipment is manufactured in-house at our fully equipped facility using advanced tools like plasma cutters, TIG/MIG welding systems, and hydrostatic/dye penetrant testing machines. We ensure compliance with industry standards such as ASME and GMP, delivering reactors that not only meet safety and durability benchmarks but also enhance your operational productivity. Whether you need a batch reactor or a continuous flow unit, we provide end-to-end customization, design validation, and support throughout the project lifecycle.

Products

GMP Reactors

GMP Reactors (Good Manufacturing Practice Reactors) are highly specialized vessels designed for industries where regulatory compliance, product purity, and process consistency are critical—especially in the pharmaceutical, biotech, chemical, and food industries. These reactors are engineered to meet strict GMP, FDA, and cGMP guidelines, ensuring hygienic design, traceability, and ease of validation throughout the production process.

At Harsha Engineers, we manufacture customized GMP-grade reactors that meet international standards and support high-quality production in sterile or semi-sterile environments. Built with SS316L or SS304 materials and mirror-polished internal surfaces (Ra < 0.4 µm), our reactors minimize the risk of contamination, support clean-in-place (CIP) and steam-in-place (SIP) processes, and provide complete documentation (DQ, IQ, OQ, PQ) for regulatory auditing.

These reactors include precision temperature control systems, PLC/HMI automation, sanitary fittings, and dust-free discharge mechanisms, making them ideal for handling APIs, sterile intermediates, and sensitive liquid or solid formulations.

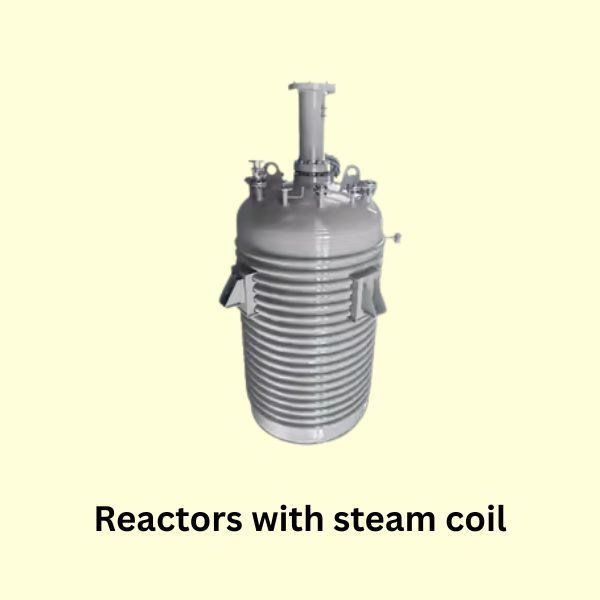

Reactors with Steam Coil

A Pre-Vacuum Autoclave, also known as a High Vacuum Autoclave, is an advanced sterilization system that ensures complete air removal from the chamber before steam is introduced. By using a powerful vacuum pump, it allows steam to penetrate deeply into porous materials, instruments with lumens, and complex loads for thorough sterilization.

This type of autoclave is ideal for hospitals, pharmaceutical industries, biotechnology labs, and research facilities, where high standards of infection control and sterility are critical. Compared to gravity autoclaves, pre-vacuum models provide faster cycles, uniform steam penetration, and superior sterilization efficiency.

Constructed with high-grade stainless steel and equipped with automated controls, safety locks, and monitoring systems, our pre-vacuum autoclaves deliver maximum reliability, safety, and performance in demanding applications.

Reactor with Limpet Coils

A Gravity Displacement Autoclave is a reliable sterilization system that uses steam to displace the air inside the chamber through gravity. It is simple to operate and highly effective for sterilizing laboratory instruments, glassware, medical tools, and culture media.

In this method, steam enters the chamber and pushes the air out through a vent, allowing saturated steam to contact every surface for complete sterilization. Gravity autoclaves are widely used in hospitals, research laboratories, and small-scale industrial applications due to their ease of use, cost-effectiveness, and consistent performance.

Built with durable stainless steel and equipped with safety features like pressure controls and locking mechanisms, our gravity displacement autoclaves ensure safe, efficient, and contamination-free sterilization.

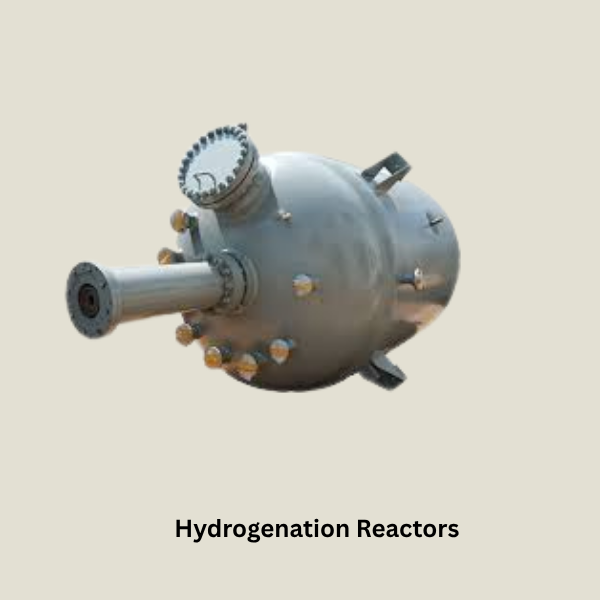

Hydrogenation Reactor

Hydrogenation reactors are highly specialized pressure vessels designed to carry out hydrogenation processes—chemical reactions where hydrogen molecules are added to unsaturated organic compounds in the presence of a catalyst. These reactors are a critical component in numerous industries including pharmaceuticals, petrochemicals, agrochemicals, food processing, and specialty chemicals manufacturing.

Hydrogenation involves the transformation of alkenes, alkynes, aromatic rings, or carbonyl-containing compounds into their saturated or partially saturated counterparts. This transformation enhances the chemical stability, shelf life, or usability of the final product. Due to the highly reactive nature of hydrogen gas and the elevated pressures and temperatures required, hydrogenation reactors are built to meet rigorous design standards, incorporating robust materials and advanced safety features.

Batch Reactors

A Gravity Displacement Autoclave is a reliable sterilization system that uses steam to displace the air inside the chamber through gravity. It is simple to operate and highly effective for sterilizing laboratory instruments, glassware, medical tools, and culture media.

In this method, steam enters the chamber and pushes the air out through a vent, allowing saturated steam to contact every surface for complete sterilization. Gravity autoclaves are widely used in hospitals, research laboratories, and small-scale industrial applications due to their ease of use, cost-effectiveness, and consistent performance.

Built with durable stainless steel and equipped with safety features like pressure controls and locking mechanisms, our gravity displacement autoclaves ensure safe, efficient, and contamination-free sterilization.

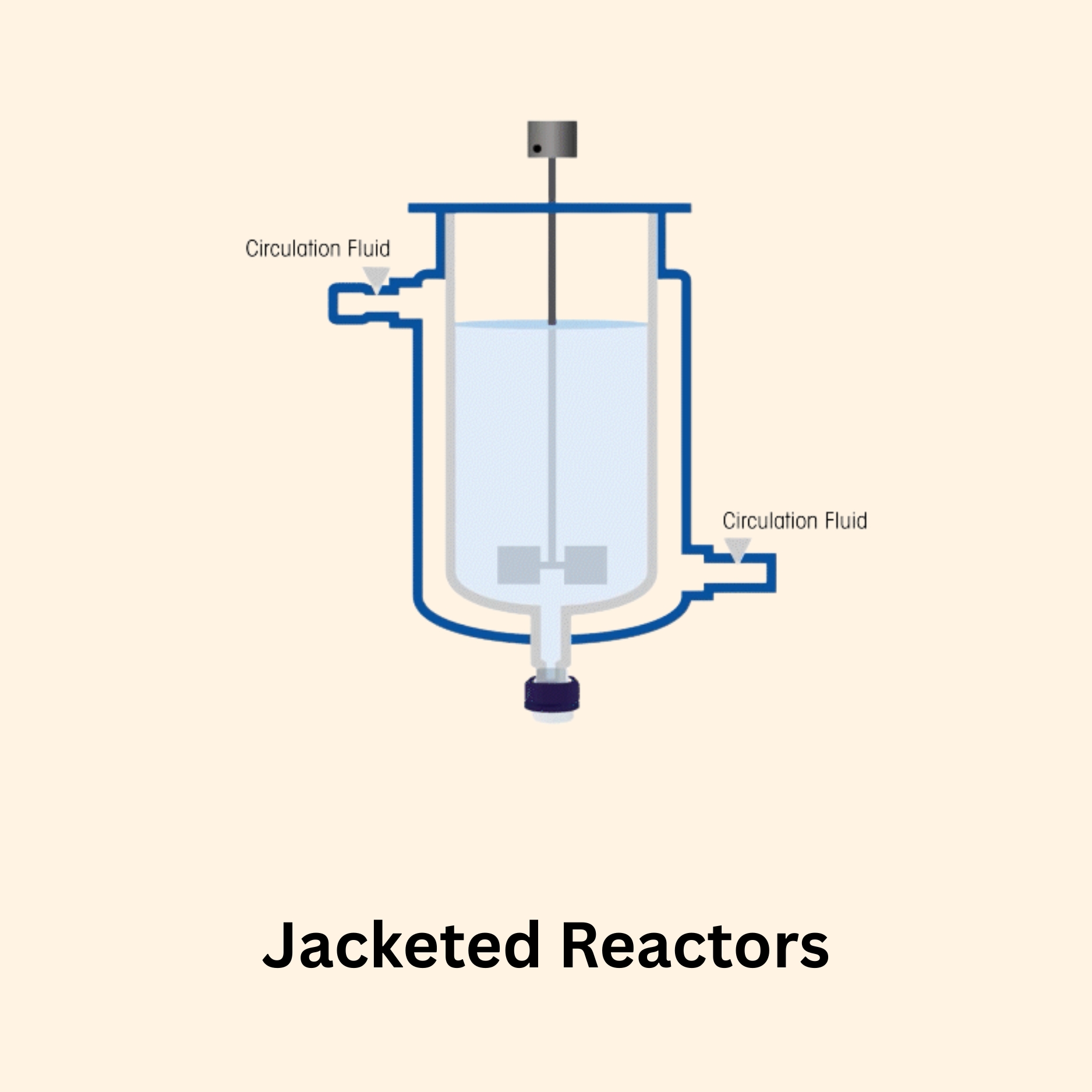

Jacketed Reactors

A Pre-Vacuum Autoclave, also known as a High Vacuum Autoclave, is an advanced sterilization system that ensures complete air removal from the chamber before steam is introduced. By using a powerful vacuum pump, it allows steam to penetrate deeply into porous materials, instruments with lumens, and complex loads for thorough sterilization.

This type of autoclave is ideal for hospitals, pharmaceutical industries, biotechnology labs, and research facilities, where high standards of infection control and sterility are critical. Compared to gravity autoclaves, pre-vacuum models provide faster cycles, uniform steam penetration, and superior sterilization efficiency.

Constructed with high-grade stainless steel and equipped with automated controls, safety locks, and monitoring systems, our pre-vacuum autoclaves deliver maximum reliability, safety, and performance in demanding applications.

Continuous Stirred Tank Reactors

A Gravity Displacement Autoclave is a reliable sterilization system that uses steam to displace the air inside the chamber through gravity. It is simple to operate and highly effective for sterilizing laboratory instruments, glassware, medical tools, and culture media.

In this method, steam enters the chamber and pushes the air out through a vent, allowing saturated steam to contact every surface for complete sterilization. Gravity autoclaves are widely used in hospitals, research laboratories, and small-scale industrial applications due to their ease of use, cost-effectiveness, and consistent performance.

Built with durable stainless steel and equipped with safety features like pressure controls and locking mechanisms, our gravity displacement autoclaves ensure safe, efficient, and contamination-free sterilization.