Rotary Mixers & Tanks

Rotary Mixers & Tanks

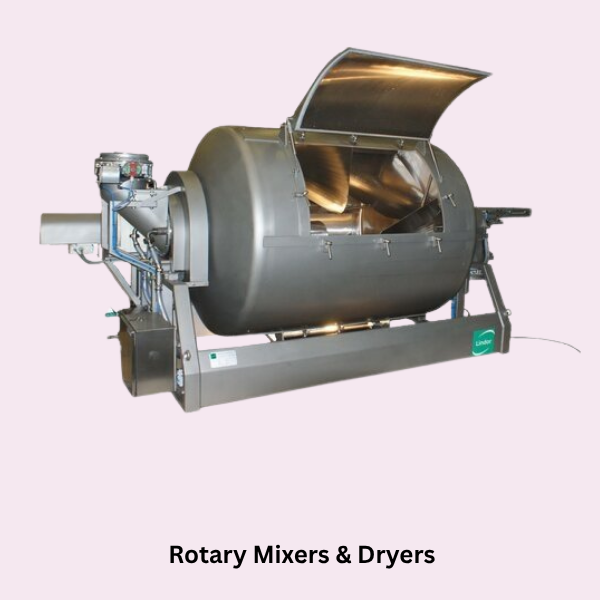

Rotary Mixers & Dryers are versatile, high-performance systems designed for the uniform mixing, drying, and processing of bulk solids and powders across various industries. These systems combine the mixing action of a rotating drum with controlled heat transfer to efficiently dry materials while ensuring homogeneous blending, making them ideal for applications where both mixing and drying are critical in a single operation.

The equipment consists of a cylindrical rotating drum that may be heated directly or indirectly through jackets, steam coils, or internal heated shafts. As the drum rotates, the material inside is gently tumbled and mixed, ensuring uniform exposure to heat. This continuous motion promotes efficient moisture removal, eliminates clumping, and enhances product consistency.

At Harsha Engineers India, our rotary mixers and dryers are available in a wide range of sizes, materials (MS, SS 304/316), and configurations (vacuum, atmospheric, or pressurized systems). They are engineered to provide high thermal efficiency, gentle product handling, and minimal energy consumption, with options for batch or continuous operation.

Technical Specifications – Rotary Mixers & Tanks

Material of Construction (MOC): MS, SS 304, SS 316, SS 316L, Hastelloy (as per process).

Capacity Range: 50 Liters to 50,000 Liters (custom-built).

Design Pressure: Atmospheric to 10 bar (depending on application).

Design Temperature: -20°C to +200°C.

Mixing Mechanism: Rotary agitator / paddle / propeller / turbine type.

Drive System: Electric motor with gearbox; optional VFD for variable speed.

Agitation Speed: 10 RPM to 200 RPM (as required).

Heating/Cooling Options: Jacketed or limpet coil with steam, hot water, or thermal oil.

Surface Finish:

Internal: Mirror polish (Ra ≤ 0.28 µm for GMP) / matt finish.

External: Matt finish / painted / SS cladding.

Mounting: Leg-mounted / skid-mounted / support structure.

Insulation: Provided with mineral wool / ceramic fiber and SS or aluminum cladding.

Nozzles & Ports: Manhole, inlet, outlet, vent, sampling, drain.

Sealing Type: Mechanical seal / stuffing box.

Discharge System: Bottom valve (butterfly / ball / flush valve).

Utilities: Steam inlet/outlet, cooling water, vacuum/pressure connections (if required).

Compliance: ASME, GMP, DIN, IS, and international standards.

A rotary mixer creates a controlled flow pattern by rotating an impeller or agitator inside a tank. Materials are effectively combined in this motion to avoid dead zones and ensure proper ingredient dispersion. The tanks can be outfitted with jackets, limpet coils, or steam coils for heating and cooling purposes, depending on the process.

- Drugs, syrups, and intermediates are mixed in the pharmaceutical industry.

- Sauces, juices, dairy, and flavor blending are all parts of the food and beverage industry.

- Chemicals, paints, resins, and adhesives are mixed in the chemical industry.

- Cosmetic Industry – preparation of creams, gels, and lotions.

- Biotechnology – fermentation and culture preparation.

- Guarantees uniform mixing with precise control.

- Suitable for production on a large or small scale.

- Allows for heating, cooling, or vacuum operations with flexibility.

- Design that uses less energy and has motor systems that work well.

- Designed to withstand continual industrial use.

Conclusion

Harsha Engineers’ Rotary Mixers and Tanks are designed for superior mixing performance, durability, and process efficiency. Our solutions assist industries in achieving consistent product quality, reduced downtime, and optimized operations through custom designs tailored to client requirements.