Emulsifiers

Emulsifiers

Emulsifiers are specialized industrial equipment designed to create stable emulsions by mixing two immiscible liquids—typically oil and water—into a uniform and homogeneous solution. They are widely used in pharmaceuticals, cosmetics, food processing, chemical manufacturing, and petrochemical industries for producing lotions, creams, sauces, ointments, and chemical blends.

Harsha Engineers India offers a range of high-efficiency emulsifiers, including inline emulsifiers, high-shear mixers, and batch emulsifying systems, equipped with precision-engineered rotors and stators. These components generate intense hydraulic shear and turbulence, breaking down droplets and dispersing them evenly, resulting in superior emulsion quality.

Emulsifiers are built using corrosion-resistant materials like Stainless Steel 304/316, and can be customized for variable speed control, vacuum operation, heating/cooling jackets, and automated CIP (Clean-in-Place) systems, ensuring versatility, hygiene, and process optimization.

Whether for large-scale industrial production or laboratory-scale trials, Harsha’s emulsifiers are designed for maximum efficiency, reliability, and consistent product output, supporting seamless integration into existing processing lines.

Emulsifiers are specialized machines used to create stable and uniform emulsions by mixing two immiscible liquids such as oil and water. They are crucial in industries where consistency, product stability, and smooth texture are essential. High-performance emulsifiers in MS, SS 304, SS 316, and GMP-compliant designs are manufactured by Harsha Engineers for use in pharmaceutical, food, cosmetic, and chemical applications.

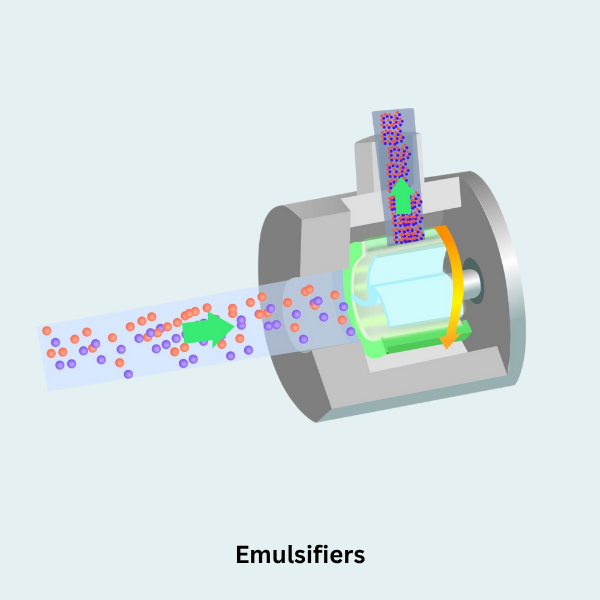

Emulsifiers operate on the principle of intense shear mixing and particle size reduction:

- The material is subjected to high-speed shear forces created by a rotor-stator or high-pressure system.

- Particles or large droplets are reduced to smaller, uniform sizes.

- This process produces a stable emulsion where two immiscible liquids remain evenly dispersed without separation.

- Constructed from GMP-grade designs and Mild Steel, Stainless Steel 304/316, and Mild Steel.

- A system of a high-speed rotor and stator for effective emulsification.

- Particle size and emulsion stability can be adjusted.

- Compact and robust construction for long-term performance.

- Simple to operate, maintain, and clean.

- Available in lab-scale, pilot-scale, and industrial-scale capacities.

Emulsifiers are widely used across diverse industries:

- Pharmaceuticals—preparation of syrups, creams, ointments, suspensions, and vaccines.

- Food & Beverages – production of mayonnaise, dressings, sauces, dairy products, and beverages.

- Cosmetics & Personal Care—creams, lotions, shampoos, conditioners, gels, and serums.

- Chemical Industry – paints, coatings, resins, and lubricants.

- Preparation of nutrient media and bio-based emulsions through biotechnology

- Produces stable and uniform emulsions with high consistency.

- Enhances texture, shelf-life, and product quality.

- Suitable for a wide range of viscosities and materials.

- Customizable design based on process requirements.

- Robust construction with dependable functionality.

- Energy-efficient operation with minimal maintenance needs.

Conclusion

Emulsifiers from Harsha Engineers are engineered to deliver precision mixing and stable emulsification across multiple industries. With their robust design, hygienic construction, and high efficiency, our Emulsifiers help businesses achieve superior product quality, consistency, and reliability in every batch.