Mixers & Blenders

Mixers & Blenders

At Harsha Engineers India, we design and manufacture a wide range of Mixers and Blenders engineered for uniform mixing of powders, granules, pastes, and liquids across various industries including pharmaceuticals, chemicals, food processing, and cosmetics. Our product line includes ribbon blenders, double cone blenders, paddle mixers, and high-shear mixers, each optimized for specific mixing requirements such as blending dry powders, achieving homogeneous mixtures, or dispersing liquids into solids. Built with robust construction and precision engineering, our mixers ensure consistent mixing performance, low power consumption, and minimal material degradation.

Each unit is fabricated using high-grade stainless steel or other process-specific materials, with options for GMP-compliant finishes, variable speed drives, vacuum or pressure operation, and automated discharge systems. Whether it’s a batch process or continuous operation, we customize the design based on material characteristics, batch size, and mixing intensity requirements. With decades of experience in process equipment manufacturing, Harsha Engineers ensures every mixer and blender meets the highest standards of quality, hygiene, and operational reliability—making us a trusted partner for efficient and scalable mixing solutions.

Products

Jet Mixers

At Harsha Engineers India, we offer high-efficiency Jet Mixers designed for fast, uniform mixing of liquids without the need for moving internal parts. Using the principle of fluid dynamics, jet mixers operate by circulating liquid through specially designed nozzles to create high-velocity jets, ensuring thorough blending and agitation. These mixers are ideal for applications in the chemical, pharmaceutical, petrochemical, and wastewater treatment industries where gentle but effective mixing is required—especially for shear-sensitive or hazardous materials.

Our jet mixers are custom-fabricated using corrosion-resistant stainless steel or other suitable alloys, and they are engineered for easy integration into both batch and continuous processes. With advantages like low maintenance, energy efficiency, and enhanced safety (due to no rotating shafts inside the vessel), jet mixers are an excellent alternative to conventional mechanical agitators. At Harsha Engineers, we provide complete design, fabrication, and installation support to ensure optimal mixing performance tailored to your specific process needs.

Ribbon Mixers

At Harsha Engineers India, we manufacture high-performance Ribbon Mixers designed for efficient and uniform blending of dry powders, granules, and low-viscosity pastes. Our ribbon mixers feature a horizontal U-shaped trough and a double helical ribbon agitator that moves material in both radial and axial directions, ensuring rapid and homogeneous mixing. Ideal for industries such as pharmaceuticals, chemicals, food processing, and cosmetics, these mixers are particularly effective in achieving uniformity in formulations with minor ingredient additions or where precision is critical.

Constructed from high-grade stainless steel or mild steel based on application requirements, our ribbon mixers are built for durability, hygienic operation, and easy cleaning. Available in various capacities, they can be customized with features like jacketed vessels for heating/cooling, dust-proof covers, discharge valves, and variable speed drives. With decades of fabrication experience, Harsha Engineers delivers ribbon mixers that combine engineering precision with robust performance—making them a trusted solution for reliable, cost-effective, and scalable mixing operations.

Ribbon Blenders

At Harsha Engineers India, we specialize in the design and fabrication of robust Ribbon Blenders for uniform and efficient mixing of dry powders, granules, and bulk solids. These blenders feature a horizontal trough with a precisely engineered double-helical ribbon agitator that moves materials in a counter-current flow—both radially and laterally—ensuring fast and homogeneous mixing. Our ribbon blenders are ideal for industries such as pharmaceuticals, food, chemicals, and agro-products, where consistent blending and batch integrity are essential.

Manufactured using high-grade stainless steel or mild steel, depending on the application, our ribbon blenders are available in various sizes and configurations. Optional features include jacketed construction for heating or cooling, variable speed drives, pneumatic or manual discharge valves, and CIP (Clean-in-Place) systems for hygienic operations. Designed for easy operation and maintenance, Harsha Engineers’ ribbon blenders offer high efficiency, low energy consumption, and long service life—making them a preferred choice for batch mixing applications requiring precision and reliability.

Octagonal Blenders

At Harsha Engineers India, we offer precision-engineered Octagonal Blenders designed for gentle and efficient blending of dry powders and granules, particularly in bulk quantities. The unique octagonal shape of the blender provides excellent tumbling action with minimal attrition, making it ideal for mixing sensitive or fragile materials in the pharmaceutical, chemical, food, and nutraceutical industries. The slow, uniform rotation ensures thorough blending while preserving the physical integrity of the materials—especially beneficial when handling crystalline or abrasive products.

Our Octagonal Blenders are fabricated from high-grade stainless steel to meet GMP standards, with options for mirror or matt finishes depending on process requirements. They are available with features such as a conical discharge valve, baffles for improved mixing, safety railing, and automated control panels. With minimal power consumption, easy cleaning, and low maintenance, Harsha Engineers’ Octagonal Blenders offer a reliable, cost-effective solution for homogeneous batch mixing—backed by our commitment to quality, customization, and long-term performance.

Doule Cone Blenders

At Harsha Engineers India, we manufacture high-quality Double Cone Blenders designed for gentle, uniform, and dust-free mixing of dry powders and granules. The symmetrical conical design allows for free-flowing movement of material inside the vessel, ensuring a homogenous blend without the use of internal blades or agitators. This makes double cone blenders particularly suitable for heat-sensitive or fragile materials commonly used in pharmaceutical, food, chemical, and cosmetic industries, where minimal shear and efficient mixing are critical to product integrity.

Our Double Cone Blenders are constructed using high-grade stainless steel with cGMP-compliant finishes and are available in a range of capacities to suit batch processing needs. The design includes a centrally mounted charging port, butterfly valve for easy discharge, and optional features like vacuum loading, spray systems for liquid addition, and automation controls. Known for low maintenance, energy efficiency, and consistent performance, Harsha Engineers’ Double Cone Blenders are a trusted solution for achieving precision mixing in demanding production environments.

Homoginizers

At Harsha Engineers India, we design and manufacture high-performance Homogenizers engineered for uniform particle size reduction and emulsion formation in liquid-based formulations. These machines are essential in industries such as pharmaceuticals, dairy, food processing, cosmetics, and chemicals—where achieving product stability, texture, and consistency is critical. Our homogenizers apply high pressure and shear force to break down particles, ensuring a fine, uniform dispersion of one phase into another, whether it’s oil into water or solid into liquid.

Built with precision using high-grade stainless steel, our homogenizers are available in both batch and continuous models, customizable to suit different viscosities, flow rates, and pressure requirements. We offer single and multi-stage homogenizers with adjustable pressure settings, advanced sealing systems, and hygienic designs that comply with cGMP standards. Backed by robust engineering and decades of fabrication experience, Harsha Engineers’ Homogenizers deliver consistent performance, long service life, and efficient operation—making them a trusted solution for critical mixing and emulsifying applications.

Collid Mill

At Harsha Engineers India, we manufacture precision-engineered Colloid Mills designed for effective size reduction, mixing, and emulsification of semi-solid and liquid materials. Ideal for applications in the pharmaceutical, chemical, cosmetic, and food industries, our colloid mills use high-speed shearing and centrifugal force to break down solids and create stable emulsions or suspensions. They are especially suited for processing viscous products like ointments, creams, sauces, adhesives, and emulsions—delivering a consistent, fine particle size distribution with excellent product texture and stability.

Constructed from high-grade stainless steel, our colloid mills are built for hygienic, corrosion-resistant performance and are easy to clean and maintain. The units are available in both vertical and horizontal configurations, with adjustable gap settings between the rotor and stator for precise control over particle size. Optional features include jacketed chambers for heating or cooling, variable speed drives, and explosion-proof designs. With a commitment to quality and reliability, Harsha Engineers offers colloid mills that combine efficiency, durability, and precision—making them an essential solution for high-shear mixing and particle reduction processes.

Impact pulverizer

At Harsha Engineers India, we design and manufacture robust Impact Pulverizers that deliver high-speed, fine grinding and size reduction of a wide variety of materials. These machines are ideal for processing minerals, chemicals, spices, pharmaceuticals, pigments, and other medium-hard to soft materials. Our impact pulverizers use a combination of impact and attrition to break down feed material, ensuring consistent fineness, high throughput, and controlled particle size. With a compact design and efficient airflow system, they ensure dust-free operation and easy discharge, making them suitable for continuous production environments.

Built with heavy-duty construction using high-grade materials like stainless steel or mild steel (based on application), our impact pulverizers are available in various capacities and configurations. Key features include balanced rotors, replaceable liners, wear-resistant hammers, cyclone separators, and dust collection systems. Easy to operate and maintain, Harsha Engineers’ Impact Pulverizers are engineered for durability, high efficiency, and trouble-free performance—making them a dependable choice for fine grinding applications in demanding industrial settings.

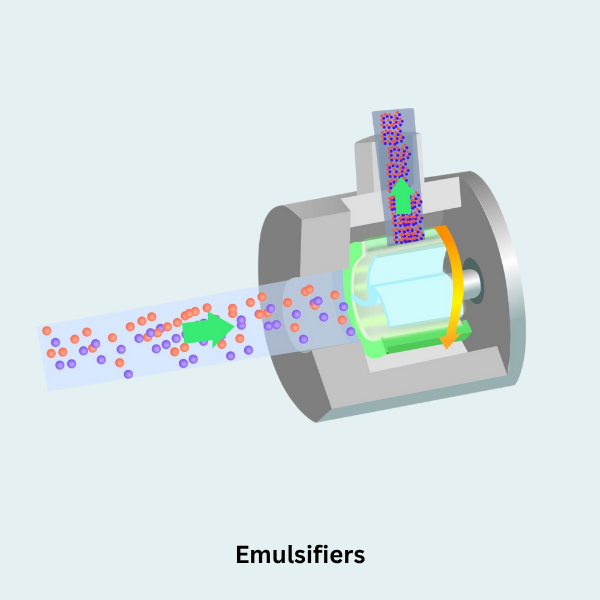

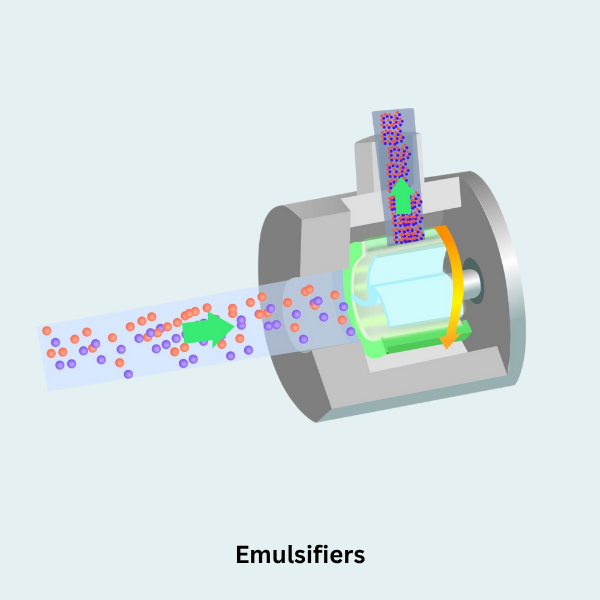

Emulsifiers

At Harsha Engineers India, we offer high-performance Emulsifiers designed for the reliable mixing and dispersion of immiscible liquids to form stable emulsions. Commonly used in the pharmaceutical, cosmetic, food, and chemical industries, our emulsifiers are ideal for applications such as creams, lotions, sauces, suspensions, and ointments—where consistent texture, stability, and product uniformity are critical. Utilizing high-shear mixing technology, our emulsifiers break down droplets to fine particle sizes, ensuring a homogenous and stable emulsion with long shelf life.

Engineered for precision and built with high-grade stainless steel, our emulsifiers are available in batch and inline configurations, with options for variable speed drives, temperature control jackets, and CIP (Clean-in-Place) systems. We customize each unit to meet specific viscosity, flow, and production requirements. With a strong focus on hygiene, durability, and performance, Harsha Engineers’ Emulsifiers deliver consistent results, energy efficiency, and seamless integration into your production line—making them a trusted choice for critical mixing and emulsifying processes.