Chemical Processing Plant Automation

Chemical Processing Plant Automation

Chemical Processing Plant Automation involves the integration of advanced control systems, instrumentation, and smart technologies to optimize the performance of entire chemical plants. At Harsha Engineers India, we design automation solutions that streamline production, safety, monitoring, and efficiency across multiple chemical processes. From raw material handling to mixing, reaction, separation, and packaging, our automation systems ensure consistent quality, reduced downtime, and enhanced safety in complex chemical environments.

Centralized Control Systems – PLC, SCADA, DCS, and HMI-based plant-wide automation.

Real-Time Monitoring – Continuous tracking of pressure, temperature, flow, pH, and level parameters.

Process Optimization – Smart algorithms to maximize yield and minimize wastage.

Automated Safety Systems – Interlocks, alarms, emergency shutdowns, and explosion-proof designs.

Data Analytics & Reporting – Cloud integration, IoT, and predictive maintenance tools.

Energy Efficiency – Optimized operations for reduced energy consumption and costs.

Custom Solutions – Flexible automation designed for specific chemical plant layouts and processes.

Bulk Chemical Production – Large-scale processing of chemicals and intermediates.

Pharmaceutical Manufacturing – Batch and continuous process automation for precision dosing.

Petrochemicals & Refining – Automated handling of flammable and hazardous materials.

Agrochemicals – Controlled production of fertilizers, pesticides, and crop solutions.

Explosives & Defense – Safe and precise chemical processing for defense applications.

Food & Beverage Chemicals – Automated blending and quality control for additives and preservatives.

Water Treatment & Effluent Plants – Automated dosing, filtration, and monitoring.

(Customizable as per project needs)

Control Platforms: PLC, SCADA, DCS, HMI interfaces

Automation Levels: Semi-automatic / Fully automatic / Remote plant operation

Communication Protocols: Modbus, Profibus, Ethernet/IP, OPC-UA

Sensors & Instrumentation: Pressure, temperature, flow, level, and chemical composition analyzers

Power Systems: Hydraulic, pneumatic, and electrical actuators

Safety Standards: ATEX, IEC, CE, ISO compliance

Data Systems: Cloud storage, IoT connectivity, predictive analytics

Improved Safety – Minimizes risks in handling hazardous chemicals.

Consistent Product Quality – Ensures precision and repeatability in processes.

Increased Productivity – Enables continuous and efficient plant operation.

Lower Operational Costs – Reduces labor dependency, downtime, and wastage.

Regulatory Compliance – Meets international chemical industry safety and environmental standards.

Scalability – Can be upgraded to accommodate future production expansion.

Frequently Asked Questions (FAQs)

Q1: What is the main benefit of automating a chemical processing plant?

Automation enhances safety, efficiency, and consistency, which are critical in chemical manufacturing.

Q2: Can Harsha Engineers India provide end-to-end plant automation?

Yes, we deliver complete automation solutions, from process design to control system integration.

Q3: Are your automation systems suitable for hazardous chemical environments?

Absolutely. Our systems are designed with explosion-proof and safety-certified components for hazardous applications.

Q4: Can automation be integrated into existing chemical plants?

Yes, we offer retrofit solutions to upgrade existing plants with modern automation.

Q5: Which industries benefit most from chemical plant automation?

Industries like chemicals, pharmaceuticals, petrochemicals, agrochemicals, explosives, food processing, and water treatment gain maximum advantages.

Related Products

Chemical Process Equipment Automation

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

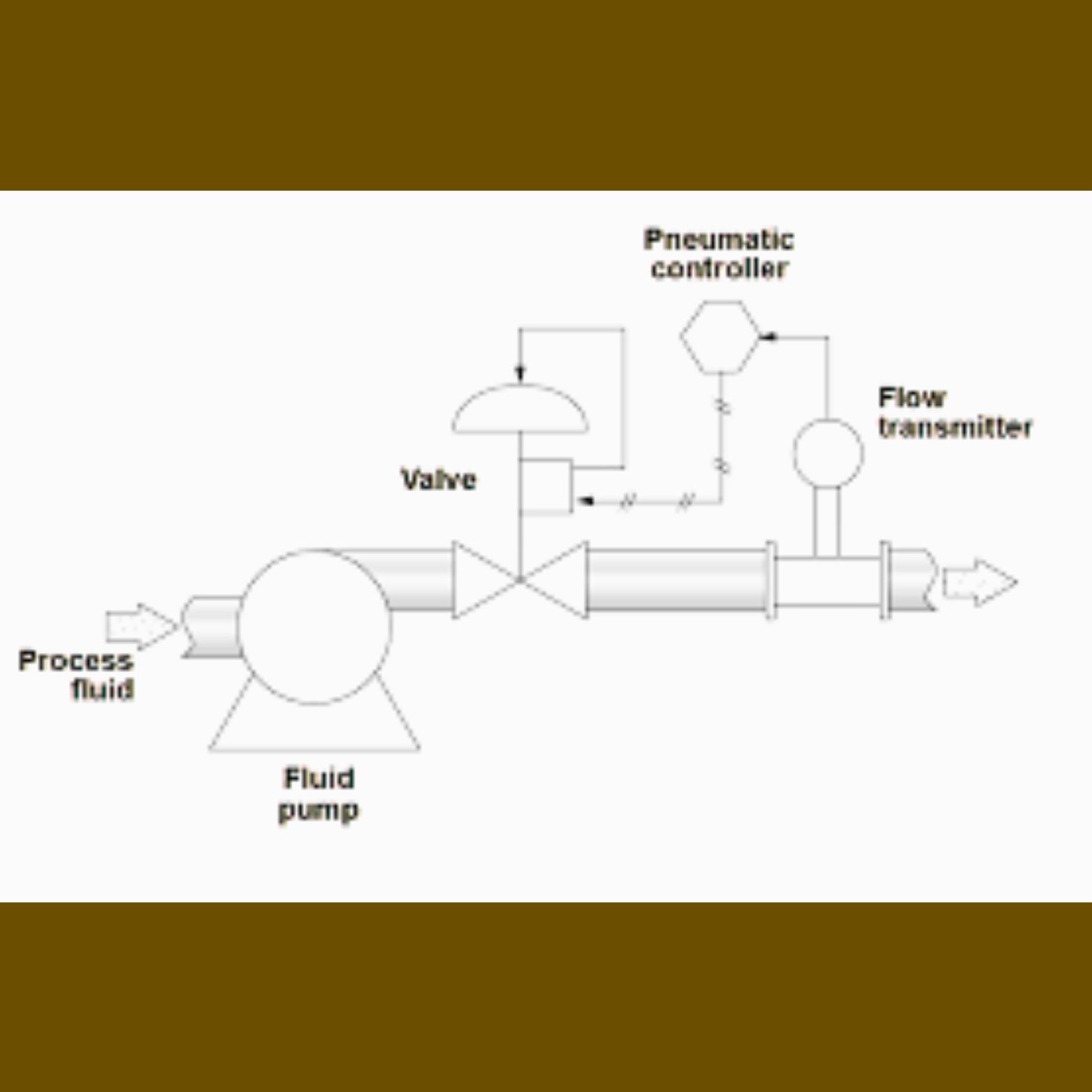

Flow Control Automation

Smart flowmeters (mass, magnetic, ultrasonic). Automated valves, pumps & dosing systems. Closed-loop monitoring for accuracy and efficiency.

Automatic Barcoding, Scanning & Data Processing

Barcode & RFID tracking solutions. Automated scanning with vision systems. Real-time data processing & ERP/MES integration. Online production monitoring dashboards.

Conveyor System Automation

Material handling and transfer automation. Intelligent sorting & routing systems. Robotic palletizing & depalletizing. Conveyor monitoring with IoT sensors.

Packing & Filling Automation

Bottle, drum, and bag filling automation. Automated weighing, sealing & labeling. High-speed packaging lines with minimum manpower.

Automation Panels

PLC, MCC & VFD-based panels. HMI & SCADA integration cabinets. Remote monitoring & control panels. Customized panel design & fabrication.