Flow Control Automation

Flow Control Automation

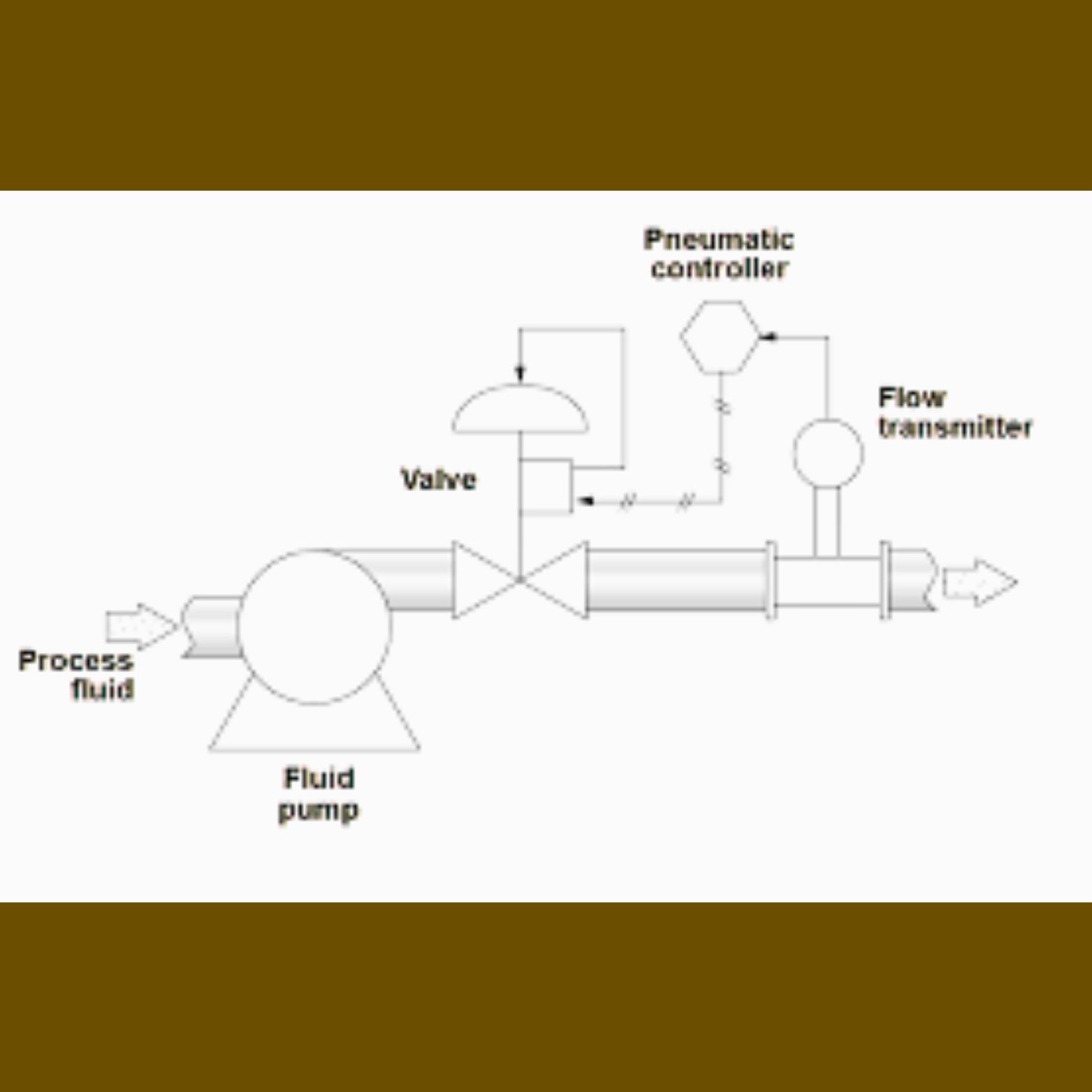

Flow Control Automation refers to the use of advanced control systems and instrumentation to regulate the movement of liquids, gases, and chemicals through pipelines and process equipment. At Harsha Engineers India, we design and integrate automated flow control systems that ensure precise measurement, monitoring, and regulation of flow rates. This enhances efficiency, product quality, and safety across industries such as chemicals, pharmaceuticals, oil & gas, food processing, and water treatment.

Accurate Flow Measurement – Integration of flow meters for precise readings.

Automated Valves & Actuators – Hydraulic, pneumatic, or electric actuation for smooth control.

Real-Time Monitoring – PLC, SCADA, and IoT-enabled systems for continuous tracking.

Remote Operation – Centralized and remote control capabilities.

Safety Mechanisms – Alarms, interlocks, and emergency shutdown systems.

Scalability – Can be adapted for small-scale to large industrial pipelines.

Energy Efficiency – Optimized operation to reduce power consumption.

Chemical Processing Plants – Control of chemical dosing, blending, and transfer.

Pharmaceutical Manufacturing – Precision flow for liquid formulations and sterile processes.

Oil & Gas Industry – Flow regulation in refineries, pipelines, and storage facilities.

Food & Beverage Industry – Consistent flow for mixing, filling, and packaging.

Water & Wastewater Treatment – Automated dosing, filtration, and distribution.

Power Plants – Cooling water, fuel, and steam flow management.

(Customizable as per project needs)

Control Systems: PLC, SCADA, DCS, HMI-based solutions

Flow Range: From a few liters/hour to several thousand m³/hour

Actuation Types: Hydraulic, pneumatic, or electric actuators

Valves Used: Gate valves, globe valves, ball valves, butterfly valves, control valves

Measurement Devices: Electromagnetic, ultrasonic, vortex, and mass flow meters

Communication Protocols: Modbus, Profibus, Ethernet/IP, OPC-UA

Safety Standards: ATEX, IEC, ISO, CE certified equipment

Precise Control – Maintains consistent flow rates for better process quality.

Enhanced Safety – Automated shutoff and emergency response mechanisms.

Improved Efficiency – Reduces manual intervention and operational errors.

Cost Savings – Optimized resource utilization lowers production costs.

Real-Time Data Access – Enables predictive maintenance and process optimization.

Flexibility – Suitable for diverse industries and fluid types.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from flow control automation?

Industries like chemicals, pharmaceuticals, oil & gas, food & beverages, and water treatment gain maximum benefits.

Q2: Can flow control systems be integrated with existing equipment?

Yes, at Harsha Engineers India, we provide custom retrofit solutions for seamless integration.

Q3: How does flow control automation improve safety?

It uses automated valves, interlocks, and emergency shutdown systems to prevent overflows, leaks, and hazardous incidents.

Q4: Do you offer remote monitoring solutions?

Yes, our systems support SCADA and IoT integration for centralized and remote plant operation.

Q5: Are your solutions customizable?

Absolutely. We design custom flow control automation systems to meet specific process requirements and industry standards.

Related Products

Chemical Process Equipment Automation

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

Chemical Processing Plant Automation

Complete plant automation using PLC/DCS systems. SCADA integration for real-time monitoring Safety interlock systems (SIS). Energy optimization and plant-wide efficiency control.

Automatic Barcoding, Scanning & Data Processing

Barcode & RFID tracking solutions. Automated scanning with vision systems. Real-time data processing & ERP/MES integration. Online production monitoring dashboards.

Conveyor System Automation

Material handling and transfer automation. Intelligent sorting & routing systems. Robotic palletizing & depalletizing. Conveyor monitoring with IoT sensors.

Packing & Filling Automation

Bottle, drum, and bag filling automation. Automated weighing, sealing & labeling. High-speed packaging lines with minimum manpower.

Automation Panels

PLC, MCC & VFD-based panels. HMI & SCADA integration cabinets. Remote monitoring & control panels. Customized panel design & fabrication.