Automatic Barcoding, Scanning & Data Processing

Automatic Barcoding, Scanning & Data Processing

Automatic Barcoding, Scanning & Data Processing is the integration of barcode printing, scanning devices, and intelligent data management systems to streamline identification, tracking, and documentation processes. At Harsha Engineers India, we design customized automation solutions that enable industries to print, scan, and process data automatically, reducing manual errors and increasing operational efficiency.

Barcode Printing & Labeling – High-speed automatic barcode generation and labeling.

Advanced Scanning Systems – Laser, CCD, and camera-based barcode readers for fast and accurate data capture.

Real-Time Data Processing – Direct integration with ERP, MES, and SCADA systems.

Wide Barcode Support – Compatible with 1D, 2D, and QR codes.

Seamless Integration – Works with conveyors, packaging machines, and warehouse systems.

Data Security – Encrypted data transfer and storage for reliable records.

User-Friendly Interfaces – Easy operation with HMI, touchscreen panels, and IoT connectivity.

Manufacturing & Assembly Lines – Tracking of parts, components, and finished products.

Pharmaceutical Industry – Secure labeling and tracking for compliance and traceability.

Food & Beverage Industry – Expiry date labeling, product identification, and stock management.

Retail & Warehousing – Automated inventory management and logistics operations.

Automotive Industry – Part traceability and defect tracking.

Logistics & Supply Chain – Fast identification and movement tracking of goods.

Chemical & Agrochemical Industry – Safe labeling and traceability of hazardous products.

(Customizable as per client requirements)

Barcode Types: 1D, 2D, QR codes

Printing Technology: Thermal transfer, direct thermal, inkjet, or laser

Scanning Speed: Up to 1,000+ scans per second

Data Connectivity: USB, Ethernet, Wi-Fi, Bluetooth, IoT-enabled

Software Integration: ERP, SAP, MES, SCADA, cloud-based analytics

Control Systems: PLC, HMI, or standalone PC-based systems

Operating Environment: Dust-proof, shock-resistant, and industrial-grade enclosures

Error-Free Operations – Eliminates manual data entry mistakes.

Faster Processing – Increases productivity with quick scanning and tracking.

Improved Traceability – Provides accurate product and batch history.

Cost Savings – Reduces manpower and paperwork.

Regulatory Compliance – Meets industry standards for traceability and labeling.

Seamless Integration – Works with existing automation and ERP systems.

Enhanced Security – Encrypted data ensures safe and reliable operations.

Frequently Asked Questions (FAQs)

Q1: What industries can benefit from automatic barcoding and scanning?

Industries such as pharmaceuticals, food & beverage, logistics, automotive, chemicals, and retail benefit the most.

Q2: Can the system integrate with existing ERP or automation software?

Yes, at Harsha Engineers India, we design solutions compatible with ERP, SAP, MES, and SCADA platforms.

Q3: What barcode types are supported?

Our systems support 1D, 2D, and QR codes for flexible applications.

Q4: Is the solution customizable for high-speed production lines?

Yes, we provide custom high-speed barcoding and scanning solutions tailored to production requirements.

Q5: Do you provide end-to-end solutions?

Yes, we offer complete systems, including barcode printers, scanners, data processing software, and integration services.

Related Products

Chemical Process Equipment Automation

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

Chemical Processing Plant Automation

Complete plant automation using PLC/DCS systems. SCADA integration for real-time monitoring Safety interlock systems (SIS). Energy optimization and plant-wide efficiency control.

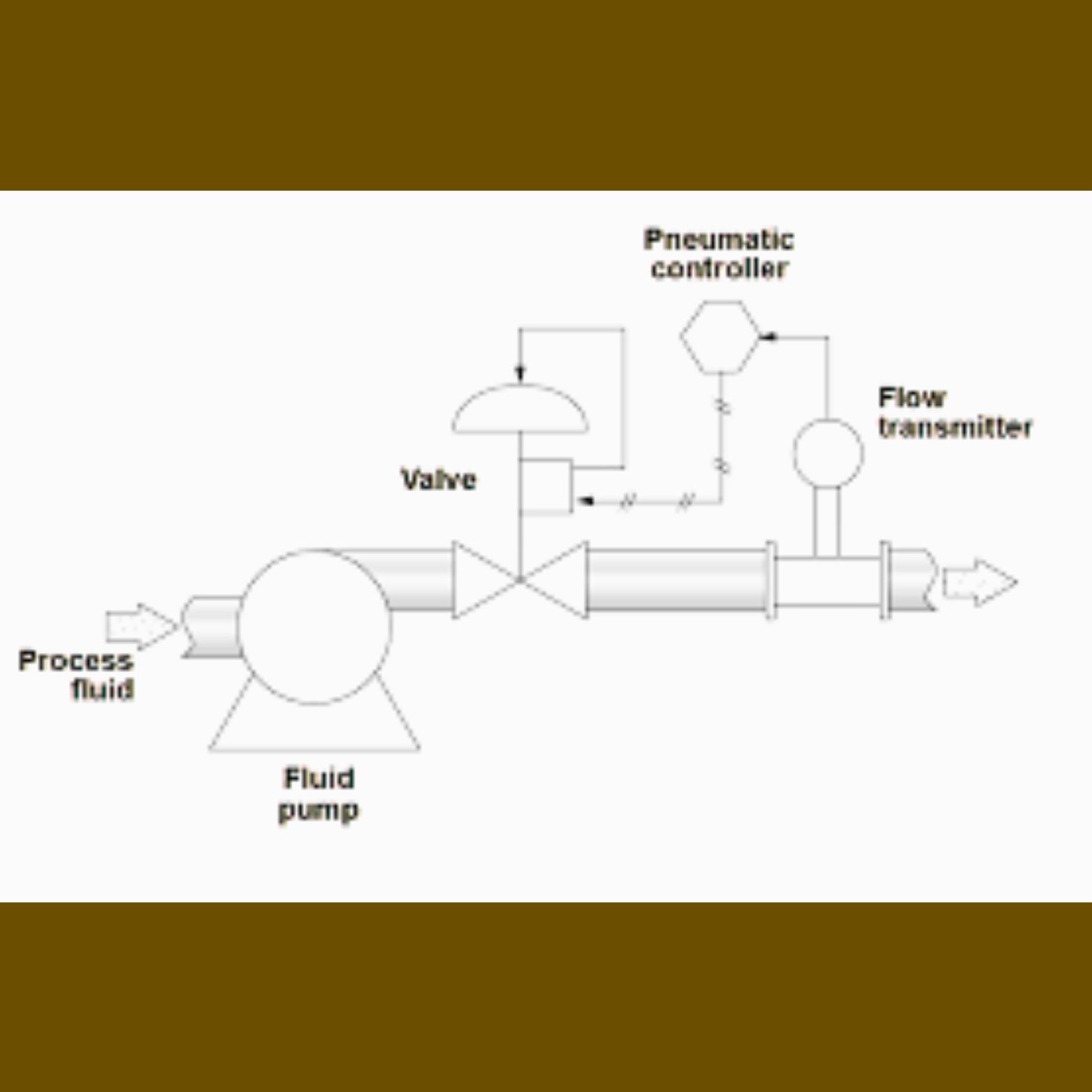

Flow Control Automation

Smart flowmeters (mass, magnetic, ultrasonic). Automated valves, pumps & dosing systems. Closed-loop monitoring for accuracy and efficiency.

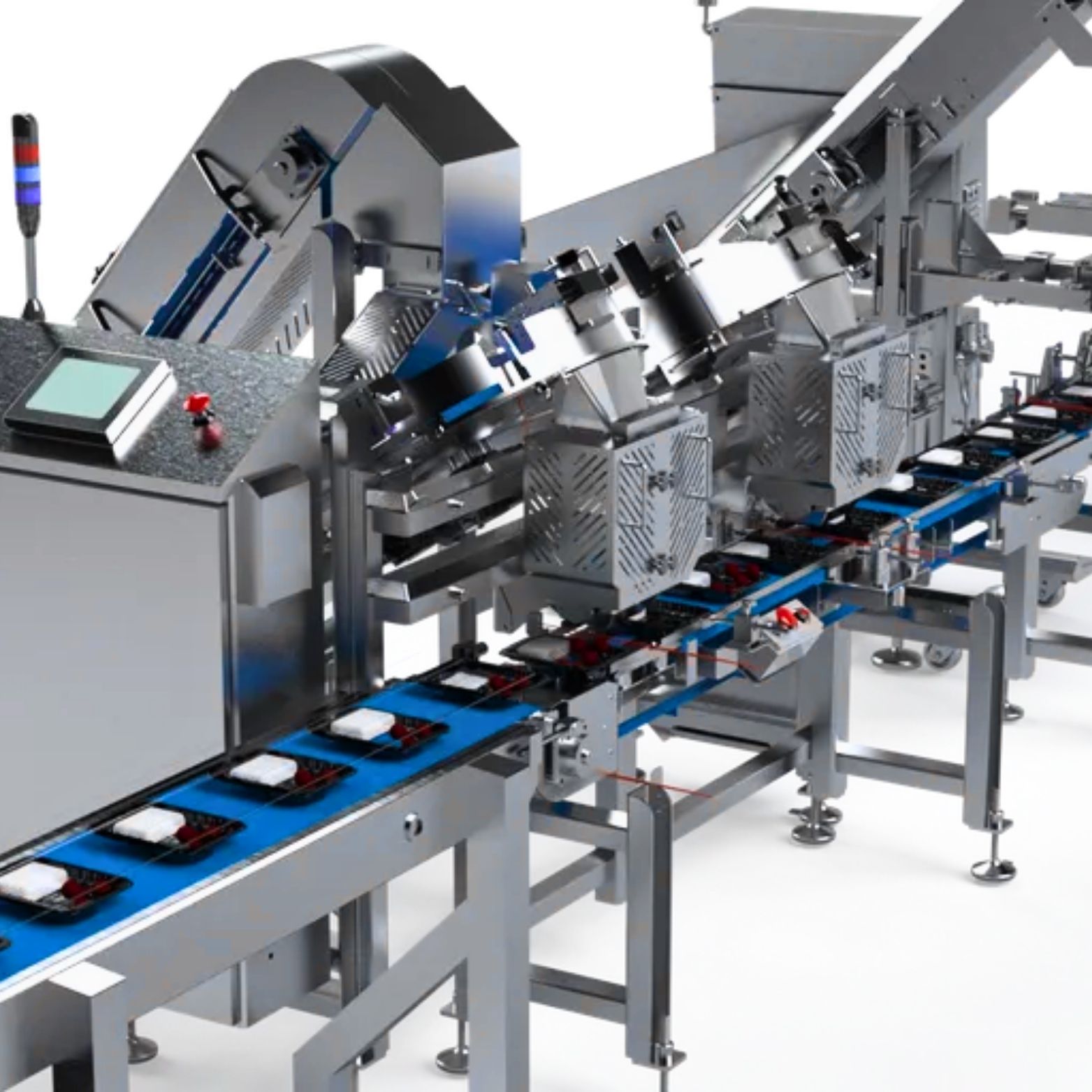

Conveyor System Automation

Material handling and transfer automation. Intelligent sorting & routing systems. Robotic palletizing & depalletizing. Conveyor monitoring with IoT sensors.

Packing & Filling Automation

Bottle, drum, and bag filling automation. Automated weighing, sealing & labeling. High-speed packaging lines with minimum manpower.

Automation Panels

PLC, MCC & VFD-based panels. HMI & SCADA integration cabinets. Remote monitoring & control panels. Customized panel design & fabrication.