High-Quality Pressure Vessels for Industrial Applications

Custom-Engineered Pressure Vessels

Engineered for Strength, Safety, and Seamless Performance

At Harsha Engineers, we specialize in the design and fabrication of high-performance pressure vessels that are built to safely contain gases or liquids at varying pressures and temperatures. Our vessels are custom-manufactured in accordance with international codes such as ASME Section VIII, IS 2825, and IBR, ensuring superior quality and reliability across industrial applications.

Available in both vertical and horizontal orientations, our pressure vessels are made using top-grade materials like SS316, SS304, MS, Alloy Steel, and Duplex Stainless Steel depending on your process requirements. Each unit is designed to endure internal pressure, temperature variations, and corrosive environments, making them ideal for chemical processing, pharmaceuticals, food & beverage, oil & gas, power generation, and more.

We offer vessels with features such as jackets for heating/cooling, insulation with cladding, manholes for access, lifting lugs, baffles, agitators, and nozzle configurations as per your specific needs. All vessels undergo rigorous testing, including hydrostatic and radiographic inspection, and can be provided with third-party certifications (TUV, SGS, BV) as required.

With an in-house design and fabrication team, Harsha Engineers ensures that every pressure vessel is optimized for your process, enhances safety, and delivers long-term operational performance with minimal maintenance.

List of Products

Auto Clave

An autoclave is a specialized pressure vessel designed to carry out sterilization and other chemical processes requiring elevated temperature and pressure. It operates by using steam at high pressure to kill microorganisms, remove contaminants, and ensure complete sterilization of equipment, raw materials, or finished products. Autoclaves are widely used in pharmaceutical, chemical, food processing, healthcare, and research laboratories for sterilizing instruments, glassware, media, and even large-scale industrial components.

They come in different sizes and types—such as vertical, horizontal, portable, and industrial-grade—depending on the application. With safety features like pressure controls, locking systems, and temperature monitoring, autoclaves guarantee reliable, consistent, and contamination-free results. Beyond sterilization, they are also used in curing composites, vulcanizing rubber, and processing materials that require controlled heat and pressure.

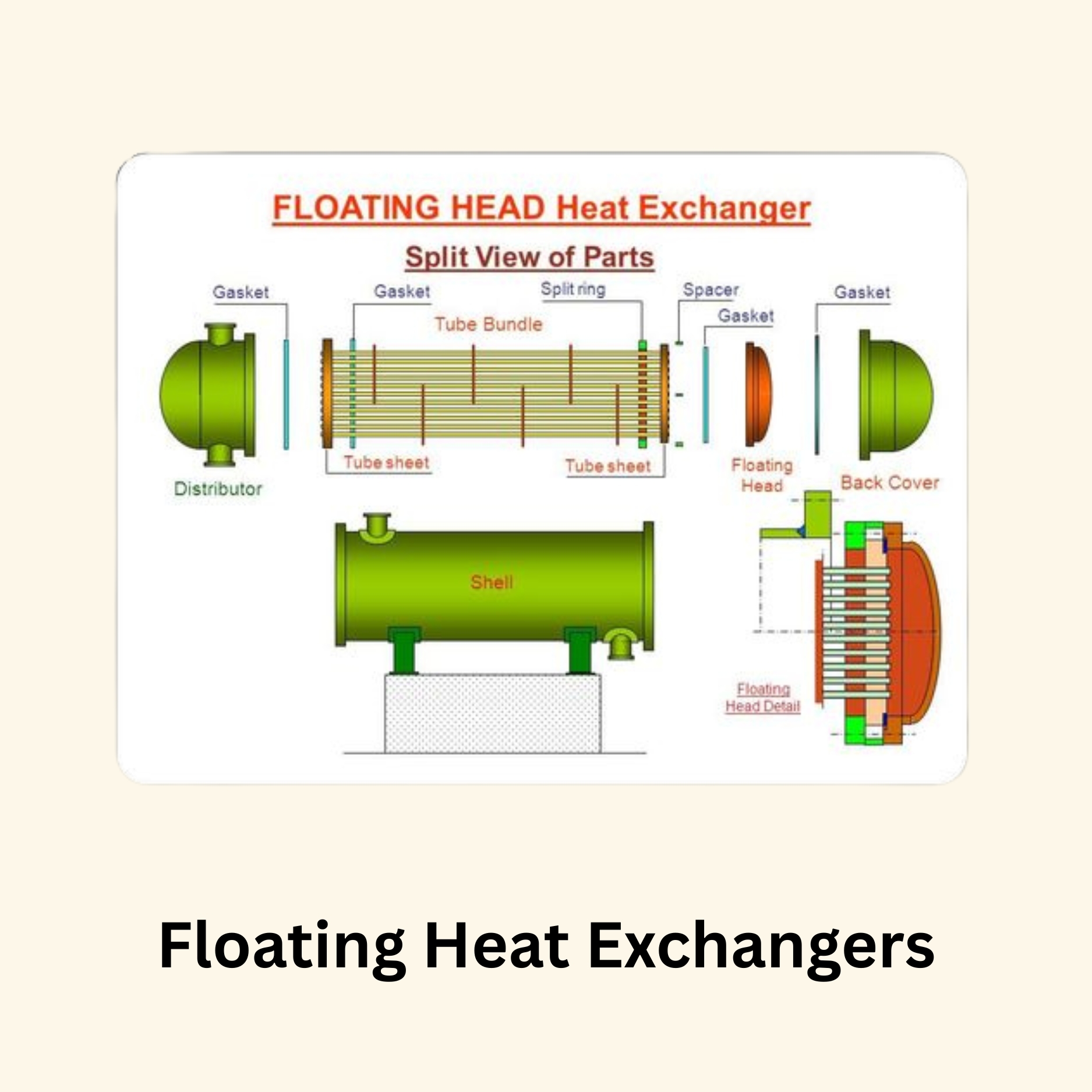

Heat Exchangers

Our Heat Exchangers are designed to deliver maximum efficiency in transferring heat between two fluids while ensuring safety and reliability. Manufactured with precision using high-quality stainless steel or mild steel, they are suitable for a wide range of applications in chemical processing, petrochemicals, power generation, HVAC, pharmaceuticals, and food industries.

We specialize in different types of heat exchangers, including Shell & Tube, U-Tube, Multi-Pass, and Custom-Built Designs, tailored to meet specific client requirements. Each unit is rigorously tested to withstand high pressure and extreme temperatures, guaranteeing long-lasting performance and low maintenance.

Whether for heating, cooling, condensation, or evaporation processes, our heat exchangers are engineered to optimize energy usage, reduce operational costs, and maintain process consistency.

Distillation Columns

Our Distillation Columns are engineered for efficient separation and purification of liquid mixtures through controlled heating and condensation. Designed with advanced technology and precision fabrication, they are widely used in chemical, pharmaceutical, petrochemical, and food processing industries to ensure high-quality output and consistent performance.

We offer a variety of column designs including packed columns, tray columns, and custom-built systems, tailored to meet specific process requirements. Built with durable materials like stainless steel and mild steel, these columns can withstand high pressure, temperature variations, and corrosive environments.

Every distillation column is rigorously tested for safety, durability, and efficiency, ensuring smooth operation, low maintenance, and long service life. Perfect for applications such as solvent recovery, alcohol purification, oil refining, and chemical processing, our solutions help industries optimize productivity and reduce operational costs.

Film Evaporators

Our Film Evaporators are designed for efficient concentration, distillation, and purification of heat-sensitive or viscous materials. By creating a thin film of liquid over a heated surface, they allow rapid evaporation with minimal residence time, ensuring product quality and thermal stability.

Commonly used in pharmaceuticals, chemicals, food processing, and petrochemicals, film evaporators are ideal for applications such as solvent recovery, essential oil extraction, concentration of liquids, and purification of sensitive compounds.

We manufacture wiped film and falling film evaporators, customized to suit process requirements. Built with high-grade stainless steel and precision engineering, they deliver consistent performance, low energy consumption, and easy maintenance, even under demanding operating conditions.

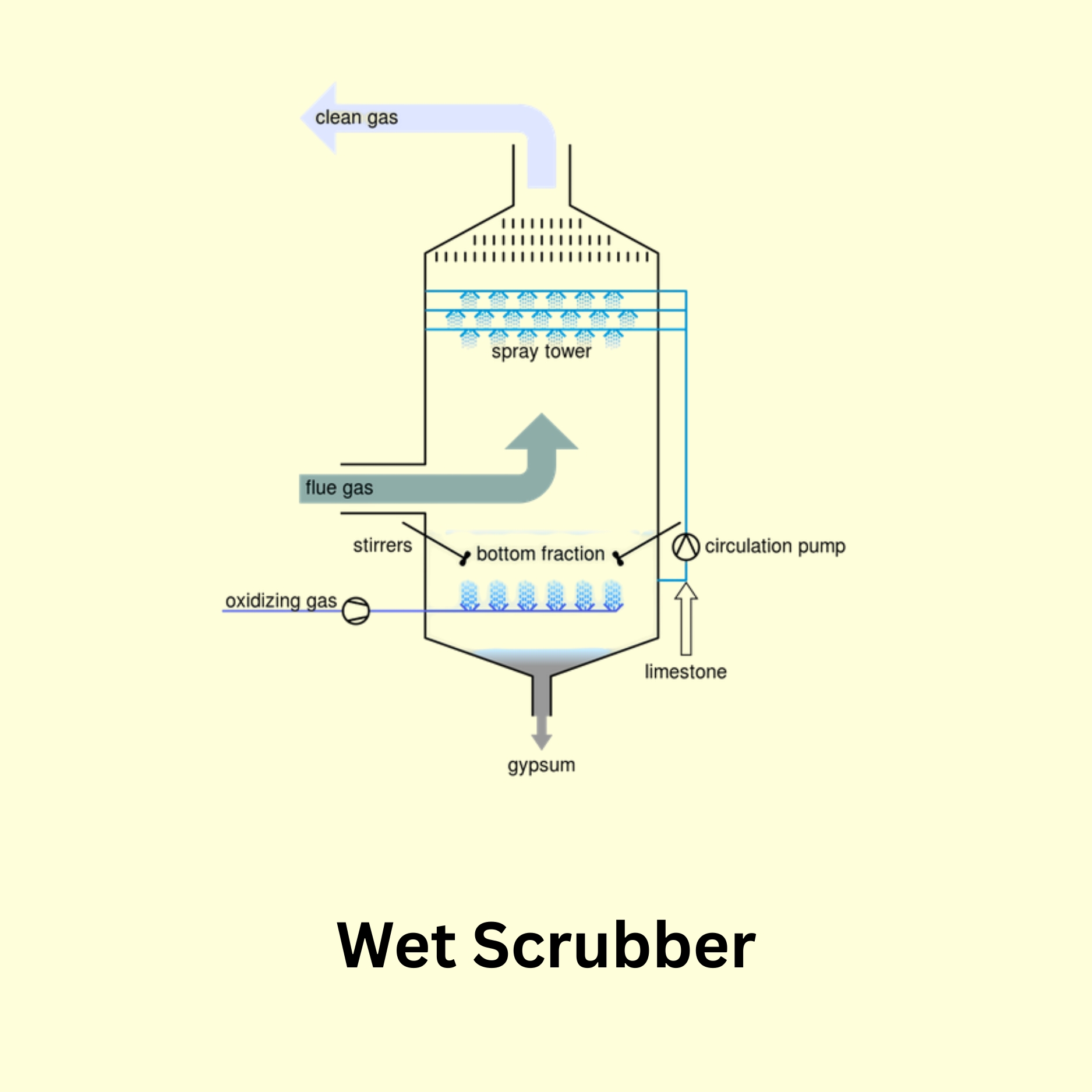

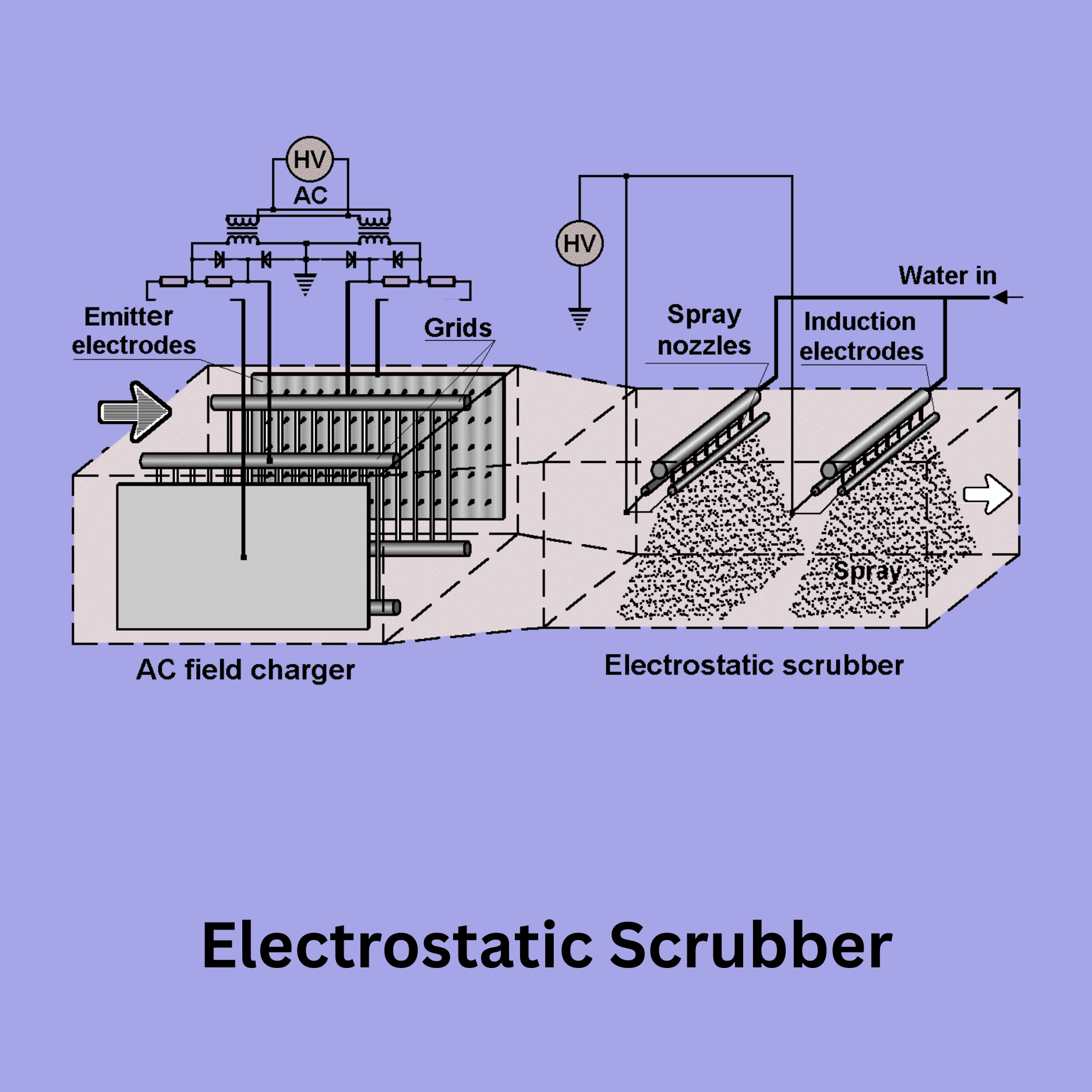

Scrubber

Our Scrubbers are highly efficient air pollution control devices designed to remove harmful gases, vapors, and particulates from industrial exhaust streams. By using liquid (commonly water or chemical solutions) to absorb or neutralize pollutants, scrubbers ensure cleaner emissions and compliance with environmental standards.

They are widely used in chemical plants, pharmaceuticals, refineries, power plants, and manufacturing units for controlling toxic fumes, dust, and corrosive gases. We offer various types including wet scrubbers, packed bed scrubbers, and venturi scrubbers, engineered to suit different industrial applications.

Built with robust materials like stainless steel, mild steel, or FRP (fiber-reinforced plastic), our scrubbers guarantee durability, low maintenance, and reliable long-term performance. Designed for efficiency, they help industries maintain a safe workplace while protecting the environment.