Automation Panels

Automation Panels

Automation Panels are specialized electrical control panels designed to manage, monitor, and control industrial processes using advanced automation technologies. At Harsha Engineers India, we manufacture custom-built automation panels integrated with PLC, SCADA, HMI, and other control systems to ensure seamless process operation. These panels serve as the central hub of automation, enabling industries to achieve higher efficiency, reliability, and safety.

PLC & SCADA Integration – Advanced process control and real-time monitoring.

Custom Panel Design – Tailored to client-specific requirements and applications.

User-Friendly HMI Interfaces – Simplified operation and data visualization.

High Safety Standards – Equipped with circuit protection, interlocks, and alarms.

IoT & Remote Access Ready – Remote monitoring, diagnostics, and control.

Modular Construction – Scalable design for easy future expansion.

Energy Efficient – Optimized power consumption with intelligent systems.

Chemical & Process Plants – Control of reactors, mixers, and flow systems.

Pharmaceutical Manufacturing – Sterile production and precise process control.

Food & Beverage Industry – Automated packaging, filling, and processing.

Automotive Industry – Assembly lines, robotic operations, and testing stations.

Water & Wastewater Treatment – Automated pumping, filtration, and dosing systems.

Oil & Gas Industry – Monitoring and controlling pipelines, pumps, and compressors.

Power Plants & Utilities – Efficient monitoring of turbines, boilers, and distribution systems.

(Customizable as per project requirements)

Panel Type: PLC Panels, VFD Panels, MCC Panels, DCS Panels, SCADA Panels

Operating Voltage: 230V / 415V AC or as required

Control Options: PLC, DCS, SCADA, HMI integration

Communication Protocols: Modbus, Profibus, Ethernet/IP, OPC-UA

Enclosure Protection: IP54 / IP65 / IP67 (dust-proof and water-resistant)

Construction Material: MS, SS, or powder-coated enclosures

Cooling Options: Natural ventilation, forced cooling, or air-conditioned panels

Safety Compliance: CE, IEC, ISO, and ATEX standards

Centralized Control – Simplifies monitoring and management of complex processes.

Improved Accuracy – Reduces manual errors with automated control.

Operational Efficiency – Enhances productivity with optimized performance.

Flexibility & Scalability – Can be expanded for future requirements.

Remote Access – IoT-enabled panels allow remote monitoring and troubleshooting.

Enhanced Safety – Protects equipment and workforce with advanced safety systems.

Cost-Effective – Reduces downtime, labor, and energy consumption.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of an automation panel?

An automation panel acts as the central control unit, integrating PLCs, drives, and instrumentation for smooth process automation.

Q2: Can you design panels for hazardous environments?

Yes, at Harsha Engineers India, we design explosion-proof and ATEX-certified panels for hazardous industries.

Q3: Are your automation panels customizable?

Absolutely. We provide custom-built panels based on specific industry needs and applications.

Q4: Do you provide installation and commissioning support?

Yes, we offer end-to-end services, from design and manufacturing to installation, commissioning, and maintenance.

Q5: Can automation panels integrate with existing plant systems?

Yes, our panels are designed for seamless integration with existing machinery and process control systems.

Related Products

Chemical Process Equipment Automation

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

Chemical Processing Plant Automation

Complete plant automation using PLC/DCS systems. SCADA integration for real-time monitoring Safety interlock systems (SIS). Energy optimization and plant-wide efficiency control.

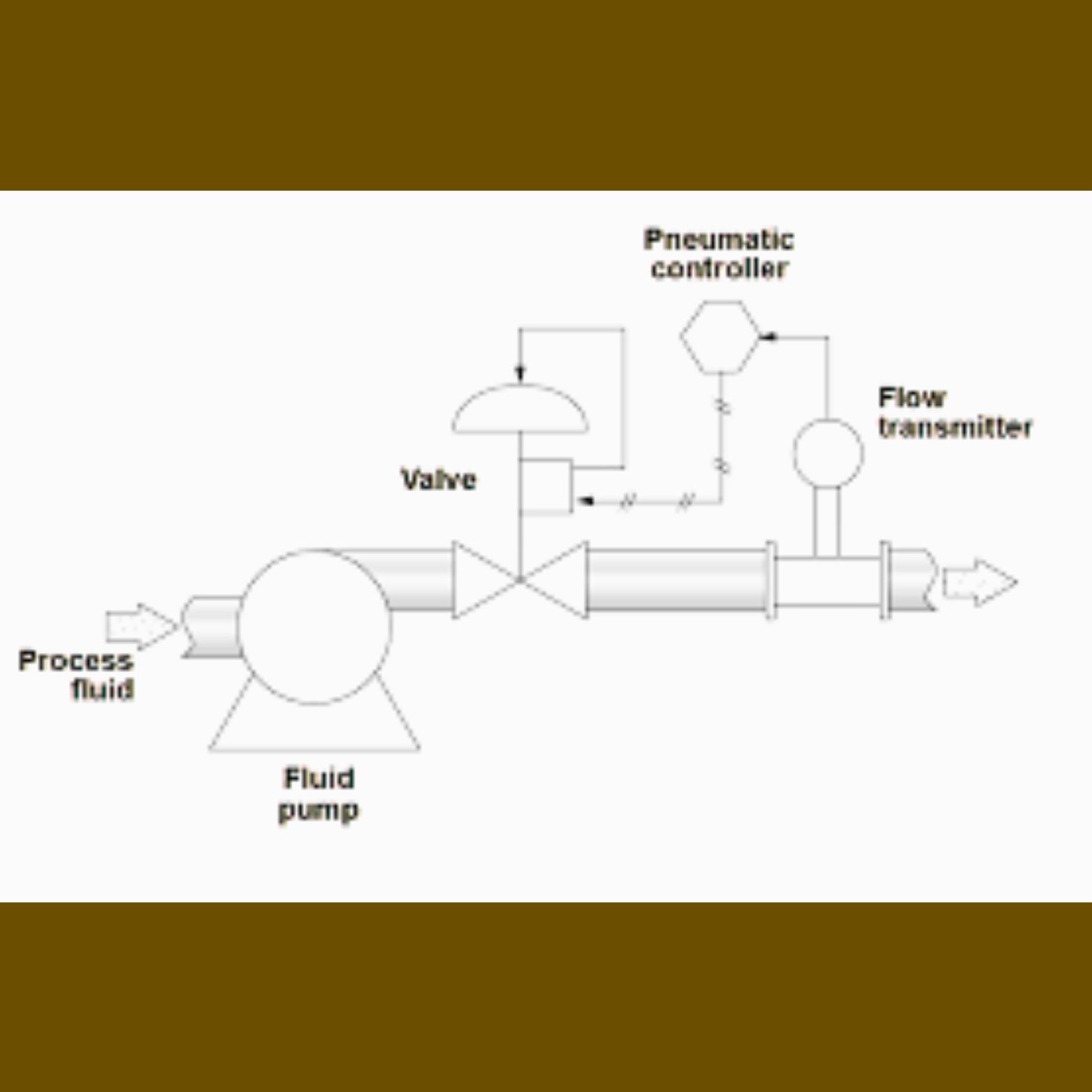

Flow Control Automation

Smart flowmeters (mass, magnetic, ultrasonic). Automated valves, pumps & dosing systems. Closed-loop monitoring for accuracy and efficiency.

Conveyor System Automation

Material handling and transfer automation. Intelligent sorting & routing systems. Robotic palletizing & depalletizing. Conveyor monitoring with IoT sensors.

Packing & Filling Automation

Bottle, drum, and bag filling automation. Automated weighing, sealing & labeling. High-speed packaging lines with minimum manpower.

Automatic Barcoding, Scanning & Data Processing

Barcode & RFID tracking solutions. Automated scanning with vision systems. Real-time data processing & ERP/MES integration. Online production monitoring dashboards.