Chemical Recievers

Chemical Recievers

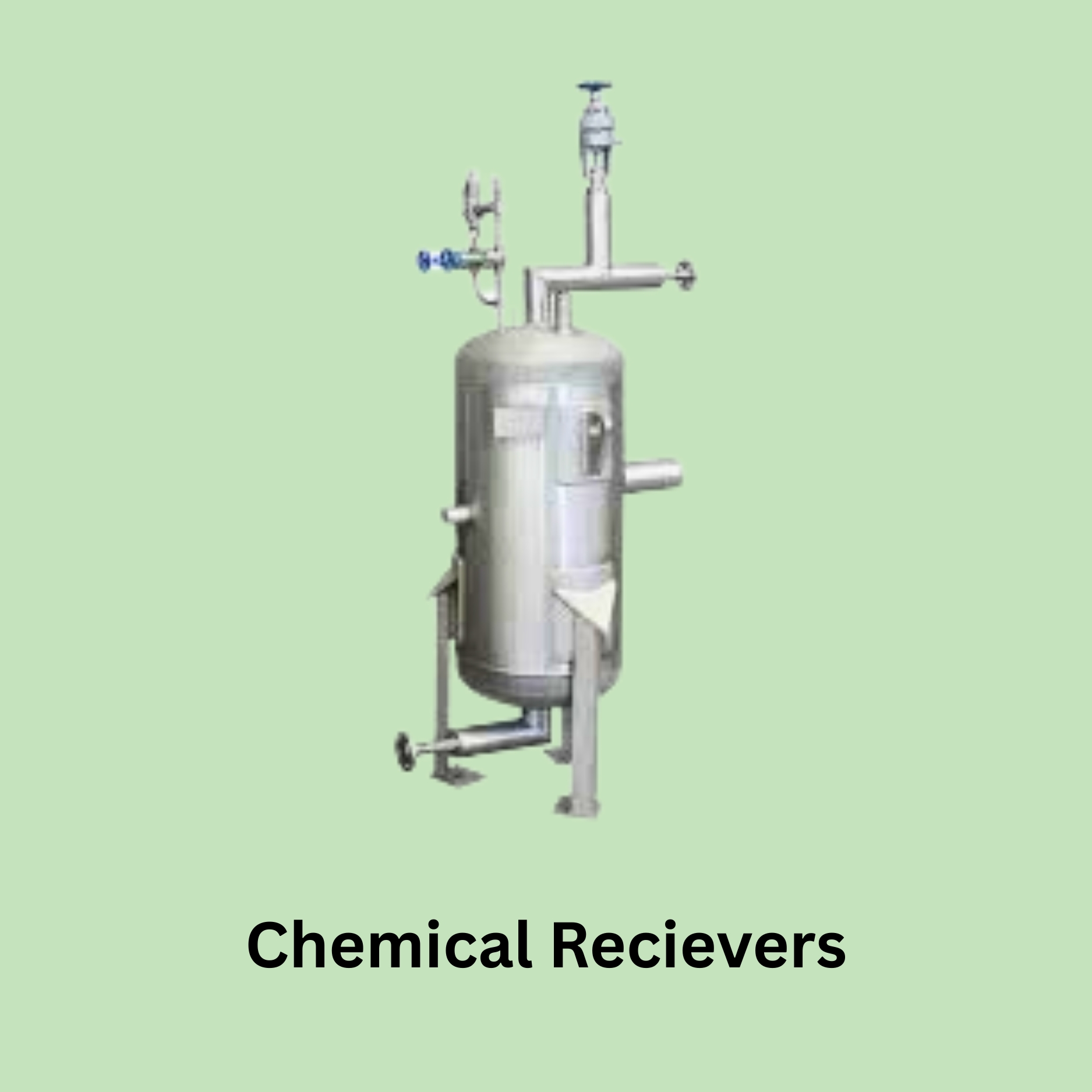

At Harsha Engineers, we design and manufacture robust Chemical Receivers for the safe storage, handling, and processing of a wide range of chemicals, solvents, and corrosive fluids. Built with high-quality Stainless Steel (SS), Mild Steel (MS), or other specialized alloys, these receivers are engineered to withstand harsh environments and aggressive chemical reactions. With options for lined interiors, insulation, and jackets, they ensure maximum protection, durability, and process efficiency.

Our Chemical Receivers are widely used in pharmaceutical, chemical, petrochemical, and food processing industries, where contamination-free storage and precise handling are critical. Available in vertical or horizontal configurations, they can be customized with safety valves, nozzles, and manholes to meet client-specific requirements. Known for their durability, low maintenance, and compliance with strict industry standards, Harsha Engineers provides chemical receivers that deliver both performance and safety in demanding industrial applications.

Material of Construction (MOC): Mild Steel (MS), Stainless Steel (SS 304 / SS 316 / SS 316L), Alloy Steel, or as per process compatibility.

Capacity Range: 100 Liters to 50,000 Liters (customized).

Design Pressure: Atmospheric to 10 bar (higher pressures on request).

Design Temperature: -20°C to +250°C (depending on MOC and service).

Orientation: Vertical (leg-mounted/skirt-supported) or Horizontal (saddle-supported).

Head Type: Dished ends / flat ends / hemispherical.

Surface Finish:

Internal: Mirror / matt finish, pickled & passivated (for SS).

External: Painted, polished, or cladded (SS/aluminum).

Nozzles & Fittings: Inlet/outlet, manhole, vent, drain, sampling port, pressure gauge, temperature sensors.

Jacket (Optional): Provided for heating/cooling with steam, hot oil, or chilled water.

Agitation (Optional): Provision for top or side-mounted agitators with mechanical seals.

Insulation (Optional): Mineral wool / PU foam with SS or aluminum cladding.

Testing: Hydrostatic and pneumatic tests as per design codes.

Compliance Standards: ASME Sec VIII Div.1, IS 2825, GMP, API, or customer specifications.

The working principle of a chemical receiver is based on safe containment and controlled transfer of chemicals:

- The receiver receives chemicals from distillation columns, condensers, or other upstream equipment.

- Through its pressure/vacuum design and airtight closures, the receiver shields the stored chemical from contamination from the outside.

- The vessel may be constructed for atmospheric, vacuum, or pressurized conditions, depending on the need.

- Through valves, pipelines, or pumps, the stored chemical can then be controlledly moved downstream to dryers, storage tanks, or packaging units.

- To keep the chemical at the right temperature, some receivers come equipped with jackets or heating/cooling arrangements.

- During manufacturing, for collecting solvents, intermediates, or filtrates for the pharmaceutical industry.

- Safe handling and storage of acids, alkalis, and solvents in chemical processing facilities

- Petrochemical Industry: Used for storing hydrocarbon fractions and condensates.

- The collection of liquid ingredients and additives is in the food and beverage industry.

- Handling pesticides, fertilizers, and intermediates in the agrochemical industry.

- Safe and contamination-free storage of chemicals.

- Customizable design to meet process requirements (capacity, pressure, material).

- High durability due to robust fabrication standards.

- Widespread application across a variety of sectors.

- Easy integration with other process equipment.

- Options for temperature control for chemicals that are sensitive.

- Pharmaceutical and chemical industries adhere to GMP and ASME standards.

Conclusion

Assuring the safe, effective, and contamination-free handling of chemicals, chemical receivers are an indispensable component of contemporary industrial processes. With their robust construction, customization flexibility, and compatibility with different process conditions, they provide industries with a reliable solution for temporary storage and transfer. By using high-quality chemical receivers, industries enhance both operational efficiency and workplace safety.