Dryers

Dryers

At Harsha Engineers, we specialize in manufacturing a wide range of Industrial Dryers designed for efficient drying of solids, powders, and other materials across diverse industries. Built with precision using Stainless Steel (SS), Mild Steel (MS), or specialized alloys, our dryers ensure uniform drying, energy efficiency, and product quality. With advanced engineering and robust construction, they are capable of handling heat-sensitive, hygroscopic, or bulk materials with ease, making them ideal for demanding industrial applications.

Our Dryers are extensively used in pharmaceuticals, chemicals, food processing, petrochemicals, and allied industries, where moisture removal is a critical step in production. We offer multiple dryer types, including Rotary Vacuum Dryers, Fluid Bed Dryers, Tray Dryers, and Spin Flash Dryers, each designed to meet specific process requirements. Known for their durability, low maintenance, and compliance with international standards, Harsha Engineers provides tailor-made dryer solutions to optimize efficiency and ensure consistent performance.

Products

Sterilizers

At Harsha Engineers, we manufacture high-quality Sterilizers designed for reliable sterilization of equipment, containers, and process materials across various industries. Built with advanced technology and durable materials such as Stainless Steel (SS), our sterilizers ensure effective elimination of microorganisms, providing a contamination-free environment for critical processes. Engineered with precision, they offer consistent performance, easy operation, and compliance with industry safety and hygiene standards.

Our Sterilizers are widely used in pharmaceuticals, food and beverage, biotechnology, chemical, and healthcare industries, where maintaining sterility is vital. Available in different capacities and configurations, they can be customized with features such as pressure control, automation, and safety systems to meet specific client requirements. With robust construction, high efficiency, and low maintenance needs, Harsha Engineers delivers sterilizer solutions that guarantee both safety and productivity in demanding industrial applications.

Centrifuge

At Harsha Engineers India, we design and manufacture high-performance centrifuges engineered for demanding industrial applications. Our centrifuges are built with robust construction to ensure safe, efficient, and continuous operation in sectors like pharmaceuticals, chemicals, and wastewater treatment. With a strong focus on quality and reliability, each unit is fabricated using high-grade materials and precision welding techniques, adhering to both national and international standards. From vertical basket centrifuges to horizontal peeler types, our solutions are customized to meet client-specific process requirements, ensuring maximum separation efficiency and low maintenance.

We understand that every industry has unique challenges, which is why our team works closely with clients to develop centrifuge systems tailored to their operational needs. Whether it’s for solid-liquid separation, sludge dewatering, or high-speed filtration, our centrifuges deliver consistent performance even in high-load conditions. Backed by years of fabrication expertise and in-house testing capabilities, Harsha Engineers ensures every centrifuge is optimized for durability, energy efficiency, and process integrity—making us a trusted partner in process equipment manufacturing.

Drying Pans

At Harsha Engineers India, we manufacture precision-engineered drying pans that are ideal for applications involving moisture removal from solids in chemical, pharmaceutical, and agro-based industries. Designed for uniform heat distribution and built using high-quality stainless steel or carbon steel, our drying pans offer superior thermal efficiency and structural integrity. Whether used as standalone units or integrated into complete drying systems, our pans are fabricated to ensure optimal drying rates, low energy consumption, and ease of cleaning—making them suitable for both batch and continuous processing environments.

Our drying pans are customizable in terms of size, thickness, and surface finish to suit a wide range of industrial drying needs. With a commitment to quality and performance, each unit undergoes stringent quality checks to ensure durability and corrosion resistance, even under high-temperature or chemically aggressive conditions. Harsha Engineers brings decades of expertise in process equipment fabrication, offering turnkey support from design and manufacturing to on-site installation and after-sales service—making us a preferred partner for efficient and reliable drying solutions.

Vibroshifters

At Harsha Engineers India, we offer high-performance vibroshifters designed to deliver precise particle separation and efficient screening across various industries, including pharmaceuticals, food processing, chemicals, and cosmetics. Engineered with robust construction and vibration-generating mechanisms, our vibroshifters ensure smooth operation, minimal downtime, and consistent product quality. Available in single, double, or triple deck configurations, these units are built to handle a wide range of materials—wet or dry—with varying particle sizes, ensuring optimal throughput and screening accuracy.

Our vibroshifters are manufactured using high-grade stainless steel for GMP compliance and are easy to dismantle, clean, and maintain, making them ideal for hygienic processing environments. Each unit is equipped with precision-balanced vibratory motors for uniform gyratory motion and long operational life. Customization options such as mesh sizes, screen diameters, and outlet positions are available to meet specific process requirements. Backed by our deep expertise in fabrication and commitment to quality, Harsha Engineers ensures that every vibroshifter delivers performance, reliability, and long-term value.

Try Dryer

At Harsha Engineers India, we specialize in the design and fabrication of industrial dryers engineered to meet the diverse drying needs of the chemical, pharmaceutical, food, and agro industries. Our dryers are built to deliver uniform and efficient moisture removal from a wide range of materials, ensuring product stability, extended shelf life, and optimal process efficiency. From tray dryers and vacuum dryers to rotary and fluid bed dryers, we offer customized solutions based on process requirements, operating temperature, and material characteristics—ensuring precise drying with minimal energy consumption.

Every dryer manufactured at our facility undergoes strict quality control, from material selection to final assembly, ensuring high performance, durability, and compliance with industry standards. We use robust construction materials like stainless steel for corrosion resistance and hygiene, and our designs incorporate user-friendly features for easy operation and maintenance. With a focus on process optimization and customer-specific solutions, Harsha Engineers delivers drying systems that integrate seamlessly into your production line, providing consistent and reliable performance.

Vacuum Tray Dryer

At Harsha Engineers India, our Vacuum Tray Dryers (VTDs) are meticulously engineered for efficient drying of heat-sensitive and hygroscopic materials under controlled temperature and vacuum conditions. Designed primarily for use in the pharmaceutical, chemical, and food industries, our VTDs ensure gentle drying without degradation of product quality. The trays are heated through conduction, and the moisture is evaporated at low temperatures under vacuum, making the process ideal for drying powders, granules, and crystalline materials. Each unit is fabricated using high-grade stainless steel for GMP compliance and corrosion resistance, ensuring safe, hygienic, and reliable operation.

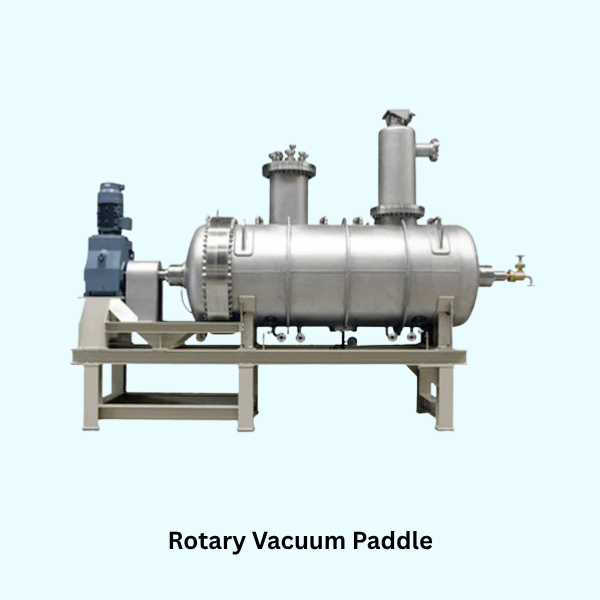

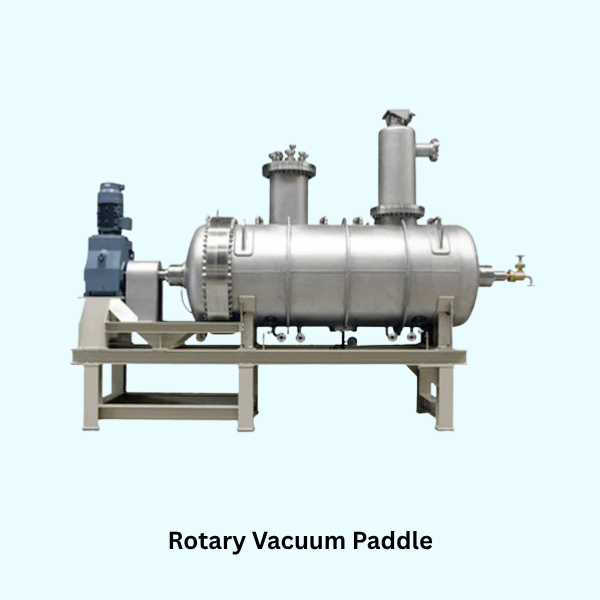

Rotary Vacuum Paddle

At Harsha Engineers India, our Rotary Vacuum Paddle Dryers (RVPDs) are engineered for highly efficient drying of sensitive, heat-labile, or toxic materials under vacuum. Ideal for applications in the pharmaceutical, chemical, and food industries, our RVPDs ensure gentle, uniform drying through indirect heating and continuous agitation by internal paddles. The rotary motion and vacuum environment accelerate moisture removal at lower temperatures, preserving product integrity while improving drying time and energy efficiency. The robust design of the vessel and mixing mechanism ensures excellent heat transfer and prevents material buildup or degradation.

Each RVPD is custom-built to client specifications, with options for heating jackets, condenser systems, solvent recovery, and automated vacuum control. Constructed from high-grade stainless steel or other corrosion-resistant alloys, our dryers are built for durability, easy maintenance, and compliance with stringent quality and GMP standards. With a focus on performance, safety, and operational reliability, Harsha Engineers provides end-to-end support—from design and fabrication to installation and commissioning—making our Rotary Vacuum Paddle Dryers a preferred solution for demanding drying processes.

Agitated Nutsche Filter Dryers (ANFDs)

At Harsha Engineers India, we manufacture precision-engineered Agitated Nutsche Filter Dryers (ANFDs) designed for efficient filtration, washing, and drying of active pharmaceutical ingredients (APIs), fine chemicals, and specialty products. ANFDs are ideal for processes requiring closed, contamination-free operations under vacuum or pressure. Our units are built to perform multiple operations—solid-liquid separation, cake washing, drying, and discharge—within a single, compact system. Featuring a fully enclosed design, they ensure safe handling of toxic, flammable, or sensitive materials, while maintaining compliance with GMP and FDA standards.

Constructed using high-grade stainless steel or special alloys, our ANFDs come equipped with hydraulically operated agitators, lifting and lowering mechanisms, vacuum systems, and solvent recovery setups. The agitator facilitates uniform cake drying, smooth discharge, and minimal product loss. With a focus on process safety, efficiency, and cleanability, Harsha Engineers delivers fully customizable ANFDs tailored to your application—offering integrated solutions that reduce manual handling, improve yield, and enhance overall process control. From fabrication to commissioning, we provide turnkey support, making us a trusted partner in solid-liquid separation technology.