Electrostatic Scrubber

Electrostatic Scrubber

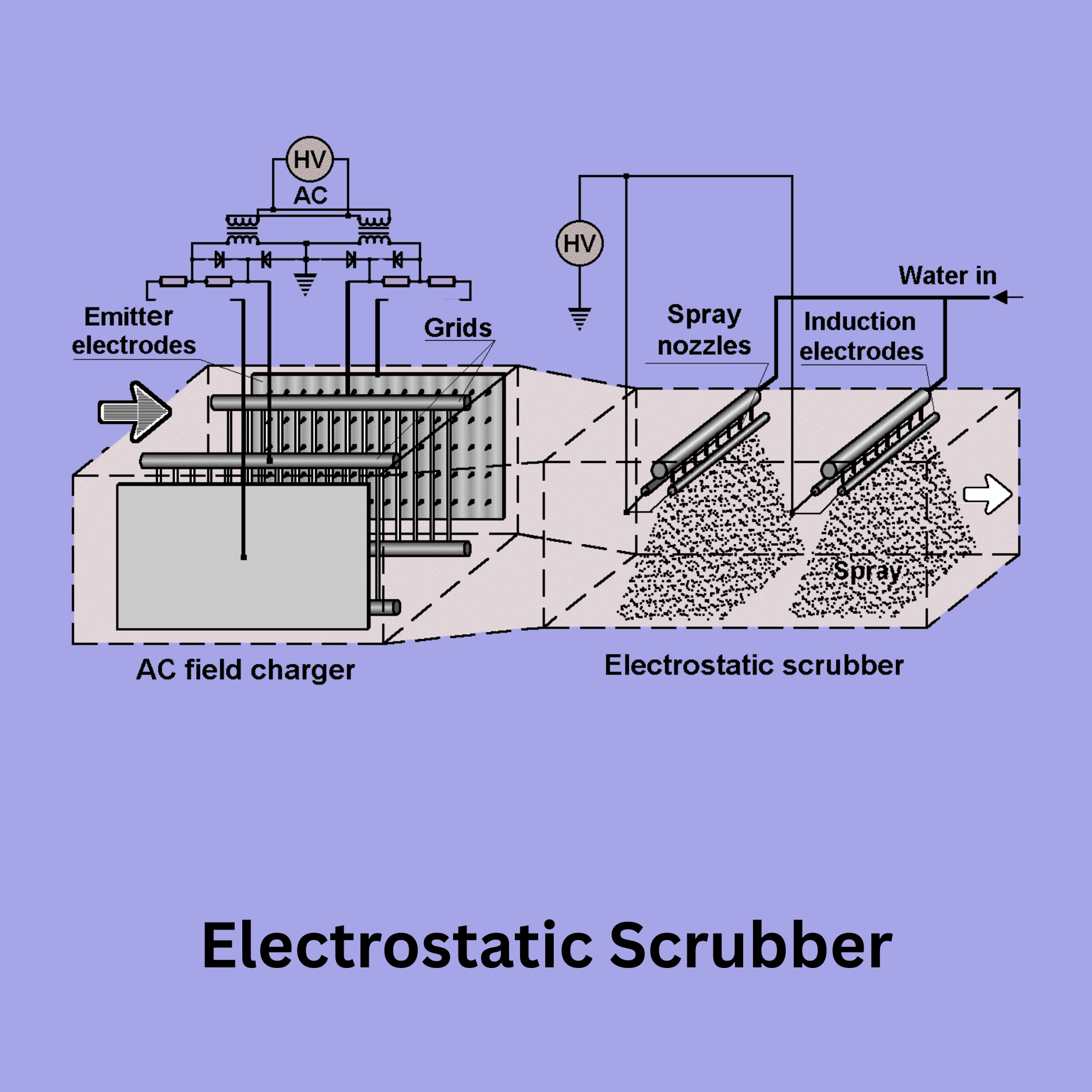

An electrostatic scrubber, also known as an electrostatic precipitator, is a highly effective air pollution control device that removes fine particulate matter from industrial exhaust gases using electrostatic forces. At Harsha Engineers India, we design electrostatic scrubbers to efficiently capture dust, smoke, and fine particles by electrically charging them and then collecting them on oppositely charged plates. This method allows for the removal of even sub-micron particles with minimal resistance to airflow, making it ideal for industries such as power generation, metal processing, chemical manufacturing, and cement plants.

Our electrostatic scrubbers are built to provide high collection efficiency, low energy consumption, and long service life. With a focus on performance and durability, we use quality materials and advanced design techniques to ensure effective operation even under high-temperature and high-volume gas flow conditions. Harsha Engineers India offers complete solutions—from design and fabrication to installation and maintenance—tailored to the specific needs of your facility, helping you meet stringent emission standards while optimizing operational efficiency.

Material of Construction (MOC): MS, SS 304/316, FRP, PP, Rubber-lined steel.

Airflow Capacity: From 500 m³/hr to 1,00,000+ m³/hr.

Voltage Range: 20 kV to 100 kV (for electrostatic charging).

Collection Efficiency: Up to 99% for fine particulates.

Scrubbing Medium: Water, alkali solutions, or customized reagents.

Design Pressure: Atmospheric to moderate positive pressure.

Compliance Standards: CPCB, EPA, and international emission norms.

The process begins when polluted gas enters the scrubber and passes through an electrostatic field. In this field, particles and aerosols become electrically charged. Once charged, they are attracted to collection surfaces or interact more effectively with scrubbing droplets. At the same time, a scrubbing liquid (usually water or a chemical solution) is sprayed into the gas stream, which absorbs and neutralizes soluble gases. The combined effect of electrostatic precipitation and liquid absorption ensures maximum pollutant removal before the clean gas is released.

- Electrostatic Scrubbers are widely used in industries that deal with very fine particulate matter and gaseous pollutants, such as:

- In the pharmaceutical industry, solvent vapors and fine powder particles are removed.

- Chemical Plants – Control of acid gases, aerosols, and corrosive vapors

- Oil mists, vapors, and odors are treated in the food and beverage industry.

- Fine dust, fumes, and mists can be captured in the mining and metallurgical industries.

- Reduced emissions of acidic gases and particulate matter from power plants and incinerators

- Extremely high efficiency for fine particulate and gaseous removal

- Handles corrosive, sticky, and high-moisture exhaust streams

- Compared to conventional wet scrubbers, this one uses less energy.

- Reduces harmful emissions, odors, and visible plumes long-lasting construction

- Long service life friendly to the environment and in line with global emission standards

Conclusion

At Harsha Engineers, we manufacture reliable and efficient Electrostatic Scrubbers designed to meet the growing demands of modern industries for cleaner emissions. By combining electrostatic and wet scrubbing technologies, our systems deliver superior pollutant removal, energy efficiency, and long-lasting performance. With customized designs for different industrial applications, our Electrostatic Scrubbers ensure sustainable and eco-friendly air pollution control solutions.