Hydraulic Accessories

What are Hydraulic Accessories?

Hydraulic accessories are essential components that support the smooth, safe, and efficient operation of hydraulic systems. They complement pumps, motors, and cylinders by ensuring fluid transfer, filtration, sealing, cooling, storage, and pressure monitoring. From high-pressure hoses and precision seals to accumulators, filters, and sensors, these accessories play a critical role in enhancing system reliability, extending service life, and ensuring operator safety.

High Performance Materials: Built to withstand extreme pressure, temperature, and environmental conditions.

Wide Compatibility: Designed for use with various hydraulic fluids and system configurations.

Leak-Proof Operation: Advanced seals and fittings minimize fluid loss and contamination.

Durable Construction: Corrosion-resistant finishes and heavy-duty designs for industrial use.

Precision Monitoring: Gauges, sensors, and switches for accurate system performance checks.

Customizable Options: Available in multiple sizes, pressure ratings, and configurations.

Hydraulic accessories are used in diverse industries and equipment, including:

Industrial Machinery: Presses, molding machines, and factory automation systems.

Construction Equipment: Excavators, loaders, bulldozers, and cranes.

Agriculture: Tractors, harvesters, and hydraulic sprayers.

Aerospace & Defense: Aircraft hydraulics, missile launchers, and defense vehicles.

Marine: Ship steering systems, deck machinery, and offshore rigs.

Automotive & Transport: Braking systems, lifts, and heavy-duty trucks.

Energy Sector: Wind turbines, oil & gas equipment, and power plants.

(Specifications vary by product type and application requirements)

Hydraulic Hoses & Fittings:

Pressure Range: Low pressure (up to 300 PSI) to high pressure (up to 10,000 PSI).

Temperature Range: –40°C to +120°C.

End Connections: BSP, JIC, NPT, SAE, DIN standards.

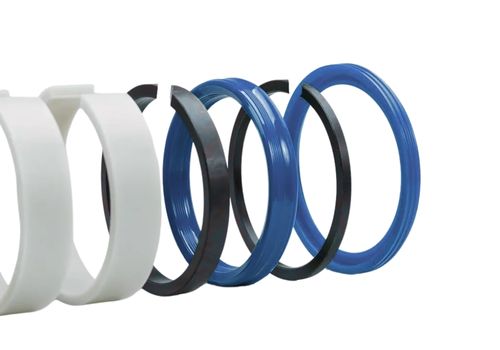

Hydraulic Seals:

Materials: Nitrile, Viton, PTFE, Polyurethane.

Types: O-rings, piston seals, rod seals, wipers.

Hydraulic Accumulators:

Types: Bladder, piston, diaphragm.

Pressure Rating: Up to 350 bar.

Capacity: 0.2 liters to 50 liters.

Hydraulic Filters:

Types: Suction, pressure line, return line.

Filtration Ratings: 3 to 25 microns.

Reservoirs & Tanks:

Material: Mild steel, stainless steel, aluminum.

Capacity: 10 liters to 5,000 liters.

Heat Exchangers & Oil Coolers:

Cooling Types: Air-cooled, water-cooled.

Capacity: 5 kW to 500 kW.

Pressure Gauges, Sensors & Switches:

Pressure Range: –1 bar (vacuum) to 1,000 bar.

Accuracy: ±0.5% FS to ±2.0% FS.

Extended Equipment Life: Protects systems from wear, contamination, and overheating.

Enhanced Safety: Prevents overpressure, fluid leaks, and operational hazards.

Improved Efficiency: Maintains optimal system performance with clean, stable fluid flow.

Reduced Downtime: Easy maintenance and replacement options minimize breakdowns.

Energy Savings: Accumulators and coolers help optimize power consumption.

System Versatility: Wide range of accessories to suit varied industrial requirements.

Hydraulic Accessories

Hydraulic Hoses & Fittings

Hydraulic Hoses & Fittings

High pressure Hydraulic Hoses & Fittings

Low-Pressure Hydraulic Hoses & Fittings

Quick Coupler Hydraulic Hoses & Fittings

Hydraulic Seals

Hydraulic Seals

O-rings Hydraulic Seals

Piston Seals Hydraulic Seals

Rod Seals Hydraulic Seals

Wipers Hydraulic Seals

Hydraulic Accumulators

Hydraulic Accumulators

Bladder Hydraulic Accumulators

Piston Hydraulic Accumulators

Diaphragm Hydraulic Accumulators

Hydraulic Accumulators

Hydraulic Filters

Suction Hydraulic Filters

pressure line Hydraulic Filters

Return Line Filters Hydraulic Filters

Others

Hydraulic Reservoirs & Tanks

Manifolds & Blocks

Heat Exchangers & Oil Coolers

Pressure Gauges, Sensors & Switches

Frequently Asked Questions (FAQs)

Q1: Why are hydraulic filters important?

Filters remove contaminants from hydraulic oil, preventing damage to pumps, valves, and cylinders, thus extending the life of the system.

Q2: What is the role of a hydraulic accumulator?

Accumulators store pressurized hydraulic fluid to absorb shocks, maintain system pressure, and provide emergency power.

Q3: How do I choose the right hydraulic hose?

Hose selection depends on working pressure, fluid type, temperature range, and end connection requirements.

Q4: What are common types of hydraulic seals?

O-rings, piston seals, rod seals, and wipers, each designed to prevent leakage and contamination in different parts of the system.

Q5: Why is heat exchange important in hydraulics?

Heat exchangers and oil coolers prevent overheating, ensuring consistent fluid viscosity and efficient performance.

Q6: Do hydraulic tanks and reservoirs need maintenance?

Yes. Regular inspection for contamination, fluid level, and corrosion ensures optimal performance.