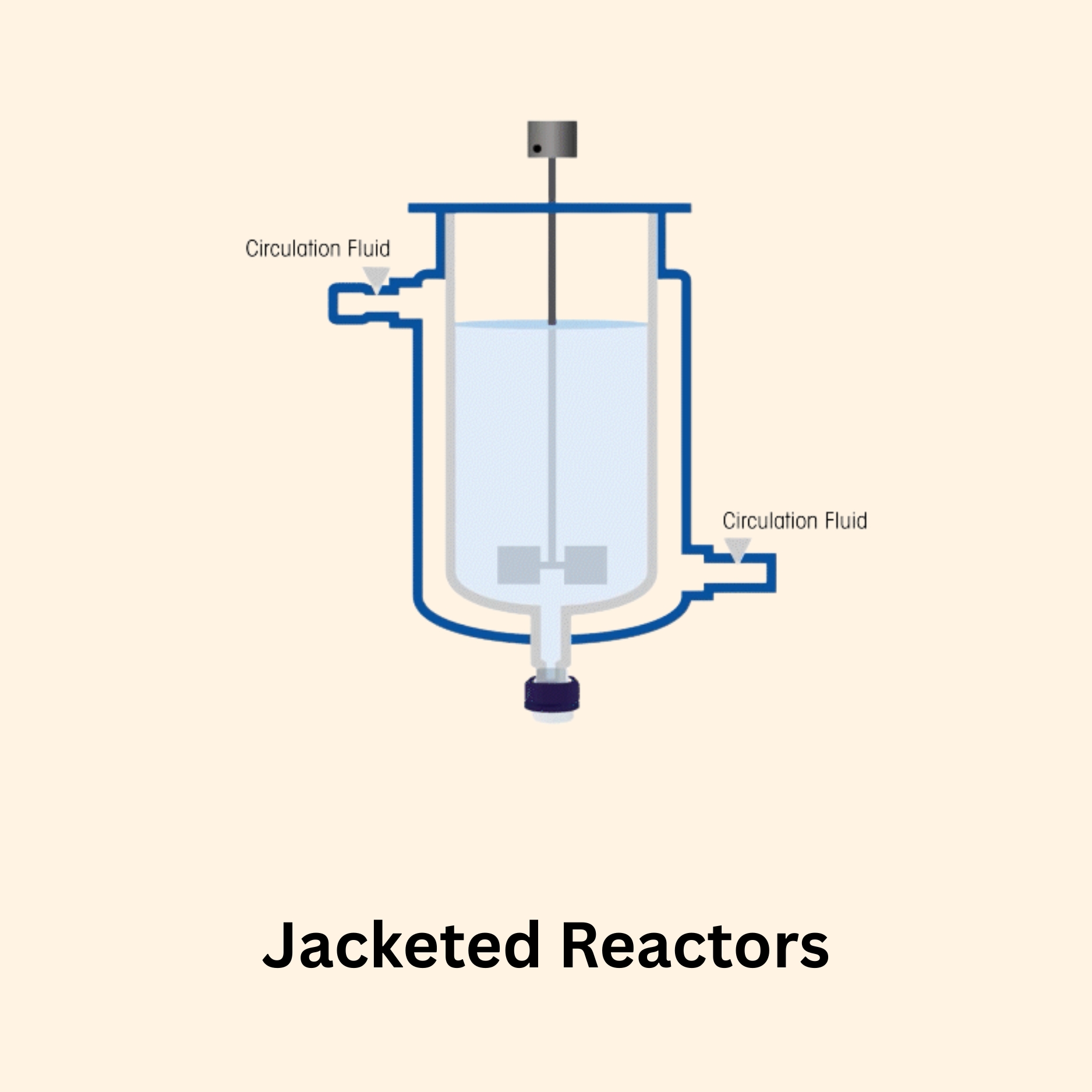

Jacketed Reactors

Jacketed Reactors

A Pre-Vacuum Autoclave, also known as a High Vacuum Autoclave, is an advanced sterilization system that ensures complete air removal from the chamber before steam is introduced. By using a powerful vacuum pump, it allows steam to penetrate deeply into porous materials, instruments with lumens, and complex loads for thorough sterilization.

This type of autoclave is ideal for hospitals, pharmaceutical industries, biotechnology labs, and research facilities, where high standards of infection control and sterility are critical. Compared to gravity autoclaves, pre-vacuum models provide faster cycles, uniform steam penetration, and superior sterilization efficiency.

Constructed with high-grade stainless steel and equipped with automated controls, safety locks, and monitoring systems, our pre-vacuum autoclaves deliver maximum reliability, safety, and performance in demanding applications.

Material of Construction (MOC): MS, SS 304, SS 316, SS 316L, Hastelloy (as per process requirement).

Capacity Range: 50 Liters to 50,000 Liters (custom-built).

Design Pressure (Vessel): Full vacuum to 10 bar (higher available on request).

Design Pressure (Jacket): Up to 6–10 bar for steam, hot oil, or chilled water circulation.

Design Temperature: -20°C to +250°C.

Jacket Type: Conventional jacket / dimple jacket / half-pipe coil jacket.

Agitator Types: Anchor, Turbine, Propeller, Helical Ribbon, Pitched Blade, or Paddle (as per application).

Drive System: Motor with gearbox, optional VFD (variable frequency drive).

Seal Type: Mechanical seal / stuffing box.

Heating/Cooling Medium: Steam, hot oil, hot water, or chilled water.

Surface Finish:

Internal: Mirror or matt polish (Ra 0.28–0.4 µm for GMP).

External: Matt finish / SS cladding / painted.

Mounting: Leg-mounted or skirt-supported.

Insulation: Mineral wool or ceramic with SS or aluminum cladding.

Safety Features: Pressure relief valve, rupture disc, vent nozzles.

Compliance: ASME, GMP, DIN, and other international standards.

A vessel with an outer jacket surrounding its shell is called a Jacketed Reactor. This jacket maintains the desired temperature within the reactor by allowing the circulation of heating or cooling media like steam, hot oil, or chilled water. Advanced controls control pressure, temperature, and process timing, while the internal agitator ensures uniform mixing of reactants. For both batch and continuous operations, this setup is ideal.

- Production of APIs, intermediates, and formulations in the pharmaceutical industry

- Industry Chemicals, including reactions like hydrogenation, chlorination, and polymerization.

- Cooking, blending, fermentation, and flavor processing are all parts of food and drink.

- Refining, fuel processing, and catalyst reactions are all part of petrochemicals.

- Provides precise temperature control for sensitive reactions.

- Ensures consistent product quality and uniform mixing.

- Design that is adaptable and appropriate for both small and large-scale production.

- High efficiency in heating and cooling operations.

- Design that can be changed to meet the needs of a particular industry.

Conclusion

Jacketed Reactors from Harsha Engineers are engineered with precision, reliability, and durability, making them an excellent choice for industries that demand controlled and efficient reaction environments. With our advanced fabrication and customization capabilities, we deliver reactors that ensure maximum productivity, safety, and long service life.