Packing & Filling Automation

Packing & Filling Automation

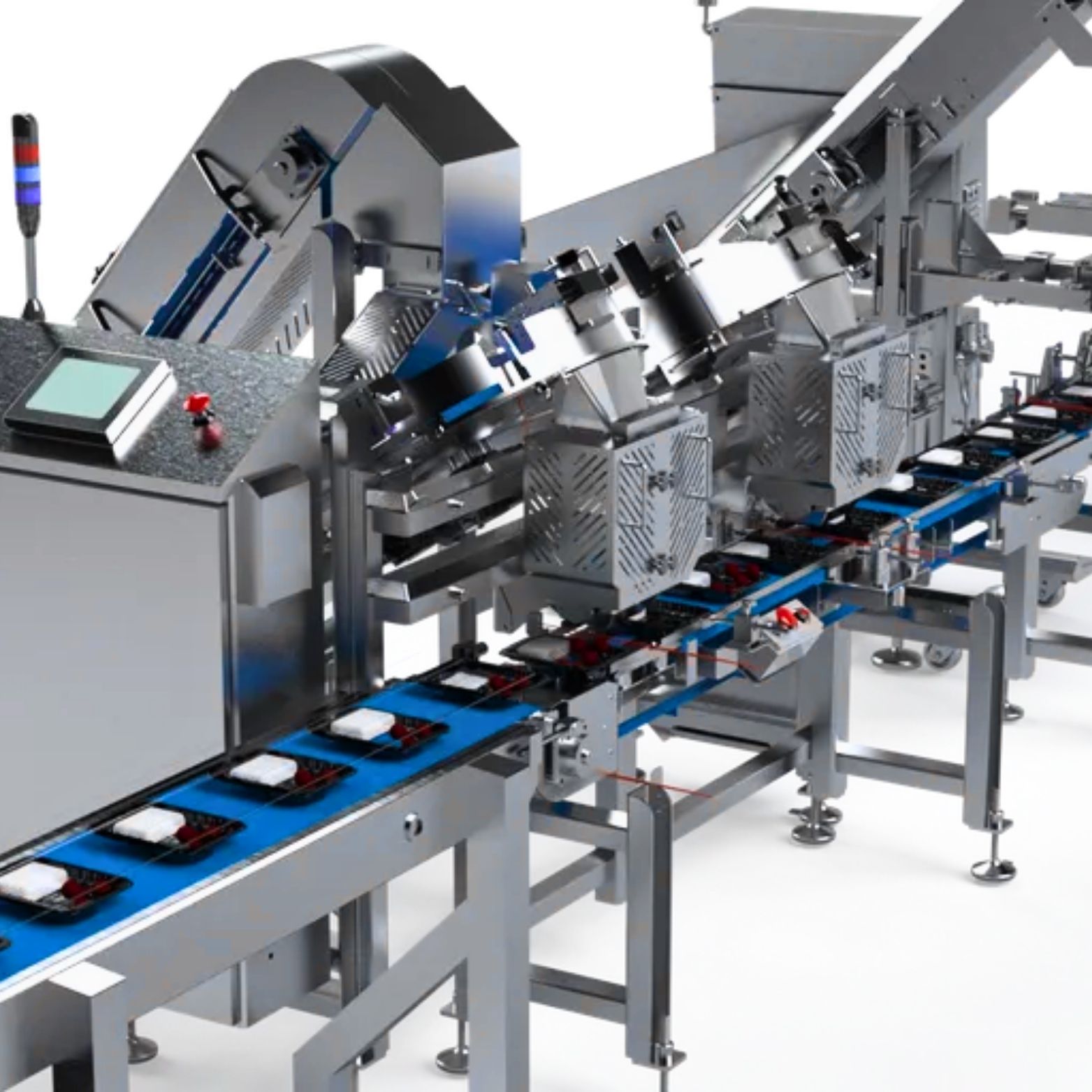

Packing & Filling Automation involves the use of automated machinery, robotics, and smart control systems to handle packaging and filling processes with high precision and efficiency. At Harsha Engineers India, we design and manufacture custom packing and filling automation systems that ensure consistency, reduce manual effort, and increase throughput. These solutions are ideal for industries requiring speed, hygiene, and accuracy in product handling.

High Precision Filling – Ensures accurate weight/volume with minimal wastage.

Custom Packaging Options – Compatible with bottles, pouches, cans, bags, drums, and containers.

Automated Sealing & Labeling – Integrated sealing, capping, and labeling solutions.

PLC & SCADA Control Systems – Smart automation for monitoring and process optimization.

Hygienic Design – Stainless steel construction for food, pharma, and chemical industries.

Versatile Operations – Handles liquid, powder, granules, semi-solids, and viscous products.

Integration Ready – Can be linked with conveyors, batching systems, and robotic arms.

Food & Beverage Industry – Packaging liquids, powders, oils, juices, and ready-to-eat items.

Pharmaceuticals – Precise filling of syrups, capsules, ointments, and sterile packaging.

Chemicals – Filling of solvents, acids, adhesives, and cleaning agents.

Agrochemicals – Automated packaging of fertilizers, pesticides, and crop protection chemicals.

Cosmetics & Personal Care – Packaging creams, lotions, shampoos, and gels.

- Industrial Products – Filling lubricants, paints, coatings, and construction materials.

(Customizable as per industry and product type)

Filling Range: From a few milliliters to 200+ liters

Filling Accuracy: ±0.2% to ±1% depending on product type

Machine Types: Gravity fillers, piston fillers, auger fillers, vacuum fillers, and volumetric fillers

Packaging Materials: Glass, plastic, metal, paper, or flexible pouches

Speed Capacity: 10 – 200+ packs per minute

Automation Levels: Semi-automatic, fully automatic, robotic-assisted

Control Systems: PLC, SCADA, HMI interfaces with IoT integration

Safety Features: Explosion-proof design (for chemicals), overload protection, emergency stops

Consistency & Accuracy – Maintains uniform filling and packaging.

Higher Productivity – Increases throughput with faster cycles.

Reduced Labor Costs – Minimizes manual intervention.

Product Safety & Hygiene – Prevents contamination in sensitive industries.

Flexibility – Can handle multiple product types and packaging sizes.

Quality Assurance – Integrated inspection, rejection, and labeling systems.

Scalable Solutions – Easily expandable for future production growth.

Frequently Asked Questions (FAQs)

Q1: Can packing & filling automation handle multiple packaging formats?

Yes, our systems are designed to handle bottles, pouches, drums, cans, and custom containers.

Q2: Are your machines suitable for food and pharmaceutical industries?

Absolutely. We use hygienic stainless-steel construction with designs compliant to industry standards.

Q3: Can these systems be integrated into existing production lines?

Yes, we provide custom retrofit solutions for seamless integration with current setups.

Q4: What level of automation do you provide?

We offer semi-automatic, fully automatic, and robotic-assisted packing & filling systems.

Q5: Do you provide customized packing & filling solutions?

Yes, at Harsha Engineers India, we specialize in designing tailor-made automation systems to match your specific industry requirements.

Related Products

Chemical Process Equipment Automation

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

Chemical Processing Plant Automation

Complete plant automation using PLC/DCS systems. SCADA integration for real-time monitoring Safety interlock systems (SIS). Energy optimization and plant-wide efficiency control.

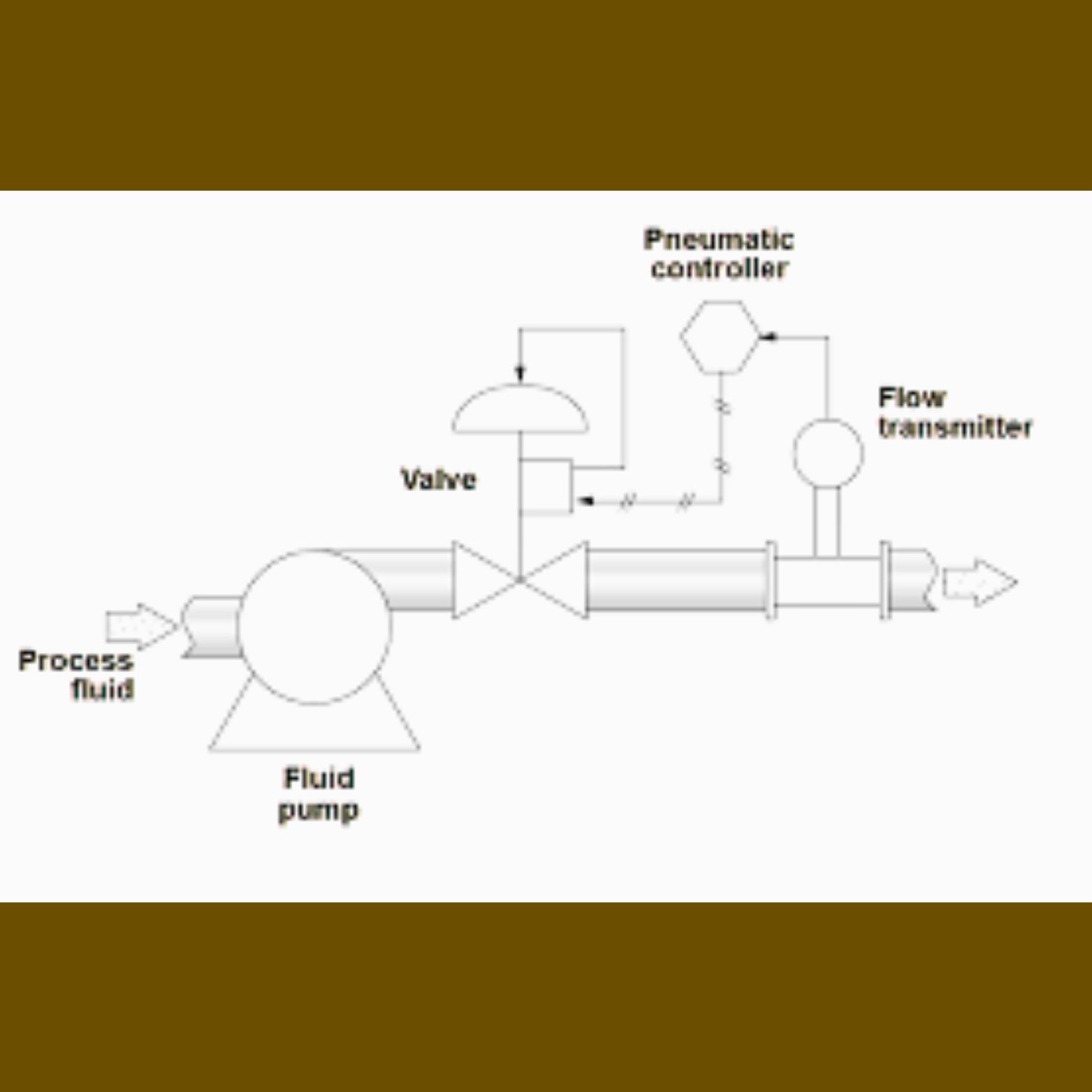

Flow Control Automation

Smart flowmeters (mass, magnetic, ultrasonic). Automated valves, pumps & dosing systems. Closed-loop monitoring for accuracy and efficiency.

Conveyor System Automation

Material handling and transfer automation. Intelligent sorting & routing systems. Robotic palletizing & depalletizing. Conveyor monitoring with IoT sensors.

Automation Panels

PLC, MCC & VFD-based panels. HMI & SCADA integration cabinets. Remote monitoring & control panels. Customized panel design & fabrication.

Automatic Barcoding, Scanning & Data Processing

Barcode & RFID tracking solutions. Automated scanning with vision systems. Real-time data processing & ERP/MES integration. Online production monitoring dashboards.