Precision-Engineered Process Equipment for Industrial Excellence

Your Trusted Partner for Industrial Process Equipment

Industrial Process Equipment Manufacturer in India

At Harsha Engineers India, we specialize in the design, engineering, fabrication, and commissioning of high-performance process equipment used in a wide variety of industries including chemical, pharmaceutical, petrochemical, food processing, cosmetics, and water treatment. Our solutions are customized to meet the most stringent process requirements and international standards such as ASME, IS, GMP, and API.

Our process equipment is crafted for critical industrial operations like heating, cooling, mixing, separating, storing, or chemically reacting fluids or solids. Each unit is meticulously engineered using cutting-edge CAD tools and fabricated using premium-grade stainless steel, mild steel, and specialty alloys depending on the client’s process, media, and operational environment.

We provide a full range of static and rotating process equipment, ensuring high mechanical strength, pressure resistance, corrosion protection, and operational efficiency. With in-house expertise and precision machining, our equipment plays a crucial role in enabling batch and continuous production systems, enhancing product quality, minimizing downtime, and improving operational safety.

From small laboratory vessels to full-scale industrial reactors and heat exchangers, Harsha Engineers ensures every product is quality-tested, durable, and compliant with customer-specific technical documentation and certifications.

List of Products

Reactors

At Harsha Engineers, we specialize in the design and fabrication of high-performance chemical reactors that meet the stringent demands of modern process industries. With over 25 years of experience, we manufacture a wide range of reactors — including jacketed, limpet coil, and pressure reactors — tailored to applications in the chemical, pharmaceutical, petrochemical, and food processing sectors. Each reactor is built using high-grade materials such as stainless steel (SS304/316), mild steel, and other alloys based on client requirements, ensuring resistance to corrosion, high pressure, and extreme temperatures.

Our reactors are precision-engineered for optimal mixing, heat transfer, and chemical reaction efficiency. From pilot-scale vessels to large industrial units, all our equipment is manufactured in-house at our fully equipped facility using advanced tools like plasma cutters, TIG/MIG welding systems, and hydrostatic/dye penetrant testing machines. We ensure compliance with industry standards such as ASME and GMP, delivering reactors that not only meet safety and durability benchmarks but also enhance your operational productivity. Whether you need a batch reactor or a continuous flow unit, we provide end-to-end customization, design validation, and support throughout the project lifecycle.

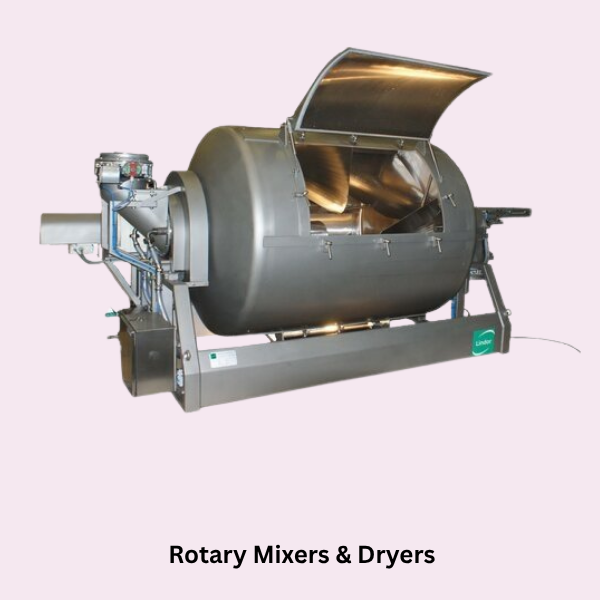

Rotory Equiment

At Harsha Engineers, we design and manufacture high-efficiency rotary equipment that serves a wide range of industrial applications, including material handling, thermal processing, and chemical production. Our offerings include rotary dryers, rotary kilns, rotary feeders, mixers, and agitators — all engineered to deliver consistent performance under high-load and high-temperature conditions. Built with robust materials and precision-balanced components, our rotary systems are designed to minimize vibration, reduce maintenance, and ensure long operational life.

Backed by decades of experience and in-house fabrication capabilities, we customize each rotary unit based on your specific process requirements — including capacity, speed, temperature range, and material of construction. Whether you need rotary equipment for drying, mixing, or conveying bulk materials, our engineering team ensures proper thermal management, sealing systems, and drive configurations to optimize your process efficiency. All units undergo rigorous quality checks, including dynamic balancing, alignment, and load testing, to guarantee reliable performance in even the most demanding environments.

Tanks

At Harsha Engineers, we manufacture a wide range of industrial storage and process tanks designed for durability, safety, and compliance with industry standards. Our tanks are custom-built for applications in chemical processing, water treatment, food & beverage, pharmaceuticals, and petroleum industries. Whether it’s storage tanks, mixing tanks, pressure-rated tanks, or jacketed tanks, each unit is fabricated using high-quality materials such as stainless steel (SS304, SS316), mild steel, or specialized alloys based on your process requirements.

Every tank is engineered for maximum operational efficiency, corrosion resistance, and structural integrity. With in-house design and manufacturing capabilities, we offer complete customization — including tank capacity, shape (vertical, horizontal), pressure ratings, internal linings, insulation, nozzles, and fittings. Our tanks undergo stringent quality control checks such as hydrostatic testing, welding inspections, and surface finishing to ensure they meet your exact specifications. From standalone tanks to integrated process systems, Harsha Engineers delivers solutions that are both reliable and cost-effective.

Receivers

At Harsha Engineers, we specialize in the design and fabrication of high-quality air and gas receivers that play a critical role in industrial compressed air systems. Our receivers are engineered to store pressurized air or gas safely and efficiently, ensuring a stable flow during peak demand while minimizing system pressure fluctuations. Available in horizontal and vertical configurations, our receivers are custom-built in various capacities and pressure ratings to suit diverse applications across industries such as manufacturing, chemical processing, and power generation.

Each receiver is fabricated using high-grade materials such as carbon steel or stainless steel and undergoes rigorous quality testing, including hydrostatic pressure tests and weld inspections, to ensure long-term reliability and safety. Designed in compliance with ASME and IS standards, our air receivers are equipped with essential accessories like safety valves, pressure gauges, and drain systems for optimal functionality. With a focus on durability, performance, and customization, Harsha Engineers provides end-to-end receiver solutions tailored to your plant’s operational needs.

Screen Vibrators

At Harsha Engineers, we design and manufacture high-performance screen vibrators that are engineered for efficient material separation, grading, and dewatering across various industries, including mining, aggregates, food processing, chemicals, and pharmaceuticals. Our vibratory screens are designed to handle a wide range of materials — from fine powders to coarse aggregates — with precision and consistency. Available in multiple configurations such as linear motion, circular motion, and elliptical motion, our screen vibrators deliver high throughput and minimal downtime.

Manufactured using robust materials and balanced vibration mechanisms, our screen vibrators offer long service life, low maintenance, and reliable performance in demanding operating environments. Each unit is customized to meet specific process requirements, including screen size, vibration frequency, deck design, and mounting style. Whether you require a single-deck or multi-deck system, our engineering team ensures smooth integration with your existing setup. With a commitment to quality and innovation, Harsha Engineers provides screening solutions that enhance productivity and operational efficiency.

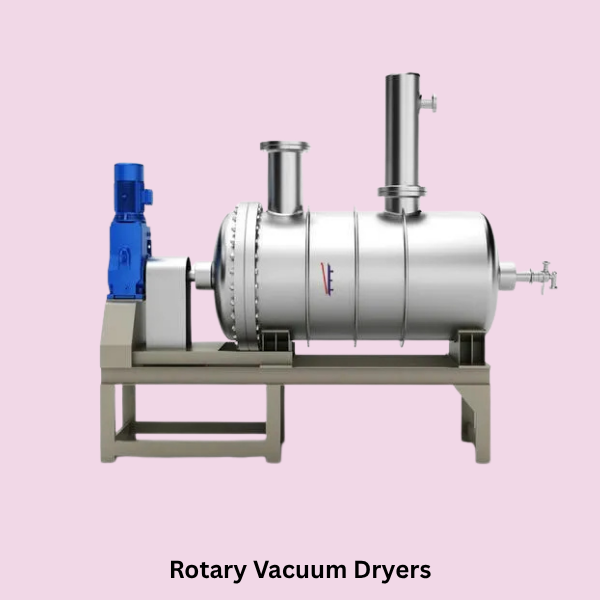

Dryers

At Harsha Engineers, we manufacture a wide range of industrial dryers engineered for efficient moisture removal and thermal processing across industries like chemicals, pharmaceuticals, food processing, and minerals. Our product line includes rotary dryers, vacuum dryers, tray dryers, and flash dryers, each designed to handle specific material characteristics such as heat sensitivity, particle size, and moisture content. Built with precision and using high-grade materials, our dryers ensure uniform drying, reduced energy consumption, and minimal product degradation.

With in-house design, fabrication, and testing capabilities, we offer complete customization based on drying temperature, residence time, material flow, and capacity requirements. Each dryer is equipped with robust drive systems, thermal insulation, and controls to optimize performance and ensure operator safety. Whether you’re processing bulk solids, powders, or granules, Harsha Engineers delivers dryer solutions that enhance productivity, extend equipment life, and meet strict industry standards.

Mixers & Blenders

At Harsha Engineers, we design and manufacture a broad range of industrial mixers and blenders tailored for uniform mixing, blending, and homogenizing of dry powders, granules, liquids, and slurries. Our product offerings include ribbon blenders, paddle mixers, double cone blenders, V-blenders, and agitator-based mixers — all engineered to meet the specific process needs of industries such as pharmaceuticals, chemicals, food, cosmetics, and agro-products. Designed for consistency, hygiene, and minimal material retention, our mixing solutions deliver efficient batch or continuous operation with high product quality.

All mixers and blenders are fabricated in-house using premium materials such as SS304/316 or mild steel, depending on your application. We offer complete customization in terms of capacity, speed, agitation type, jacketed or vacuum systems, and discharge mechanisms. Each unit undergoes rigorous testing to ensure proper mixing performance, durability, and compliance with GMP or other regulatory standards where required. With over two decades of experience, Harsha Engineers provides reliable, scalable mixing solutions that boost process efficiency and reduce downtime.

Conveyors

At Harsha Engineers, we offer a wide range of industrial conveyor systems designed for efficient, reliable, and continuous material handling across diverse industries such as manufacturing, packaging, mining, food processing, and logistics. Our product line includes belt conveyors, screw conveyors, roller conveyors, chain conveyors, and bucket elevators, each engineered to meet specific process and load requirements. Whether you’re handling bulk solids, powders, or finished goods, our conveyors are built to ensure smooth, safe, and uninterrupted material flow.

Every conveyor is custom-designed in-house to match your plant layout, throughput goals, and material characteristics. Built with durable materials like stainless steel, mild steel, or galvanized components, our systems feature high-quality drive assemblies, wear-resistant belts, and user-friendly control options. From design to installation, Harsha Engineers ensures your conveyor solution is tailored for long-term performance, reduced maintenance, and seamless integration with your existing equipment — helping you optimize productivity and reduce operational costs.