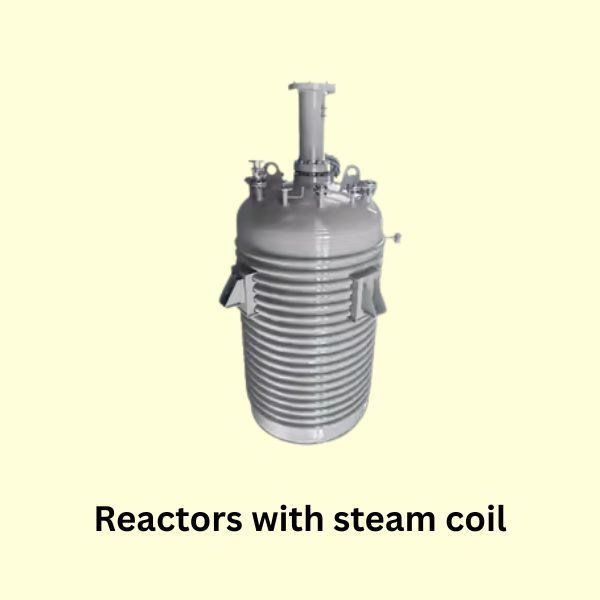

Reactors with Steam Coil

Reactors with Steam Coil

A Pre-Vacuum Autoclave, also known as a High Vacuum Autoclave, is an advanced sterilization system that ensures complete air removal from the chamber before steam is introduced. By using a powerful vacuum pump, it allows steam to penetrate deeply into porous materials, instruments with lumens, and complex loads for thorough sterilization.

This type of autoclave is ideal for hospitals, pharmaceutical industries, biotechnology labs, and research facilities, where high standards of infection control and sterility are critical. Compared to gravity autoclaves, pre-vacuum models provide faster cycles, uniform steam penetration, and superior sterilization efficiency.

Constructed with high-grade stainless steel and equipped with automated controls, safety locks, and monitoring systems, our pre-vacuum autoclaves deliver maximum reliability, safety, and performance in demanding applications.

Material of Construction (MOC): MS, SS 304, SS 316, SS 316L (as per process requirement).

Capacity Range: 100 Liters to 50,000 Liters (custom-built).

Design Pressure: Atmospheric to 10 bar (internal) / Steam coil up to 6 bar.

Design Temperature: -20°C to +200°C (depending on material & process).

Heating Medium: Steam (low/medium pressure).

Coil Type: Half-pipe coil / Limpet coil / Internal steam coil.

Agitator Types: Anchor, Paddle, Propeller, Turbine, or Helical Ribbon (as per application).

Drive System: Motor with gearbox, optional variable frequency drive (VFD).

Seal Type: Mechanical seal / stuffing box.

Surface Finish: Internal – mirror/matt polished; External – matt finish / painted / SS cladding.

Mounting: Leg-mounted / skirt-supported.

Insulation: Provided with cladding in SS / aluminum.

Utilities: Steam inlet/outlet with condensate drain, vent, and pressure relief.

Compliance: ASME, GMP, DIN, and other international standards.

In order to provide uniform heating, the reactor is outfitted with an internal or external steam coil system. By transferring heat to the reactants inside the vessel, the coil ensures efficient use of energy, controlled reaction rates, and proper mixing. Depending on the process, these reactors can also be adapted for cooling applications by circulating chilled water or cooling media through the coils.

- Polymerization, oxidation, hydrogenation, and mixing processes in the chemical industry

- Pharmaceuticals: formulation, intermediate reactions, and batch processing.

- Cooking, mixing, and temperature-controlled fermentation are all parts of food and drink.

- Refinement, blending, and catalyst-based reactions are all part of petrochemicals.

- Provides precise temperature control for sensitive reactions.

- Ensures energy-efficient heating and cooling.

- Suitable for both continuous and batch processes.

- Robust design that requires little upkeep.

- Adaptable to various capacities and operating conditions.

Conclusion

Industries that require precise temperature management, durability, and high-performance operation benefit most from steam-coil reactors. For critical industrial applications, Harsha Engineers delivers reactors tailored to your process requirements, ensuring safety, effectiveness, and long-term dependability.