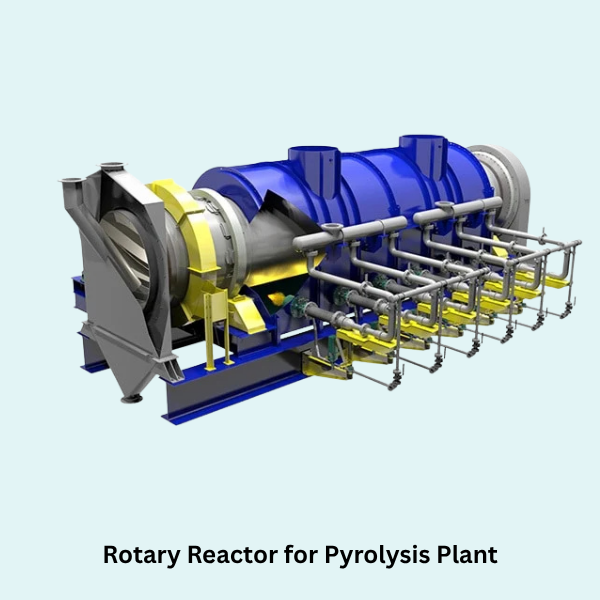

Rotary Reactor for Pyrolysis Plants

Rotary Reactor for Pyrolysis Plants

The Rotary Reactor is the heart of a pyrolysis system, specifically engineered for the thermal decomposition of organic materials in an oxygen-free environment. This high-efficiency rotating drum reactor facilitates the conversion of waste materials such as plastic, rubber, biomass, or tire waste into valuable end products like pyrolysis oil, syngas, and carbon black. Its rotary design ensures continuous mixing and uniform heat distribution throughout the reaction chamber, leading to optimized yield and enhanced thermal efficiency.

Constructed from high-grade alloy steel or stainless steel, the rotary reactor is designed to withstand extreme temperatures and corrosive environments, offering durability and long operational life. The drum is typically mounted on rollers and slowly rotated by a heavy-duty drive system. This rotation ensures even heating, prevents localized hot spots, and avoids material buildup.

Harsha Engineers India customizes rotary reactors to meet the specific requirements of pyrolysis operations, providing systems that can handle various feedstocks, batch or continuous operation, and integration with condensation units, gas cleaning systems, and control panels for complete process automation.

Material of Construction (MOC): MS, Boiler Quality Steel, or Alloy Steel (with refractory lining).

Reactor Type: Horizontal rotary kiln design.

Capacity Range: 1 TPD to 100 TPD (tons per day) feed capacity.

Operating Temperature: 300°C to 800°C (depending on feedstock).

Design Pressure: Atmospheric to slight positive pressure.

Heating System: External furnace with oil, gas, or solid fuel; indirect heating.

Refractory Lining: High-temperature resistant refractory bricks / castables for insulation.

Rotation Speed: 0.5 RPM to 3 RPM (controlled with gear drive / VFD).

Drive System: Heavy-duty electric motor with gearbox and chain drive.

Feed System: Manual / screw feeder / conveyor-based feed inlet.

Discharge System: Ash outlet with water-sealed or air-tight mechanism.

Sealing System: Air-tight seals at inlet and outlet to prevent gas leakage.

Gas Outlet: Vapour line connected to condensers for pyrolysis oil recovery.

Safety Features: Pressure relief valve, temperature sensors, emergency vent.

Mounting: Heavy-duty steel base frame / skid-mounted.

Lifespan: 8–10 years with proper refractory maintenance.

Compliance: Designed as per industrial pyrolysis and environmental norms.

A Rotary Pyrolysis Reactor operates on the principle of thermal decomposition. The rotating reactor receives waste materials like tires, plastic, rubber, biomass, and so on and heats them in an oxygen-free environment. This controlled process breaks down long-chain molecules into useful by-products like fuel oil, syngas, carbon black, and steel wire (in the case of tires). The rotary motion ensures uniform heating, continuous mixing, and consistent output quality.

- Plastic Pyrolysis Plants – convert plastic waste into fuel oil and gas.

- Tyre Pyrolysis Plants: These facilities convert used tires into steel, oil, gas, and carbon black.

- Using biomass pyrolysis, agricultural waste is transformed into bio-oil, syngas, and charcoal.

- Treatment of industrial waste—recovery of valuable byproducts and eco-friendly disposal

- Eco-friendly approach to waste management.

- Uses waste to make valuable fuels and byproducts.

- Ensures uniform efficiency throughout the entire process.

- Reduces reliance on fossil fuels and landfills.

- Durable apparatus designed for industrial-scale performance.

Conclusion

Harsha Engineers’ Rotary Reactor for Pyrolysis Plants is a sustainable, cost-effective, and efficient option for businesses that want to turn waste into useful resources. We deliver dependable pyrolysis systems that guarantee high output, durability, and eco-friendly performance thanks to our expertise in reactor design and fabrication.