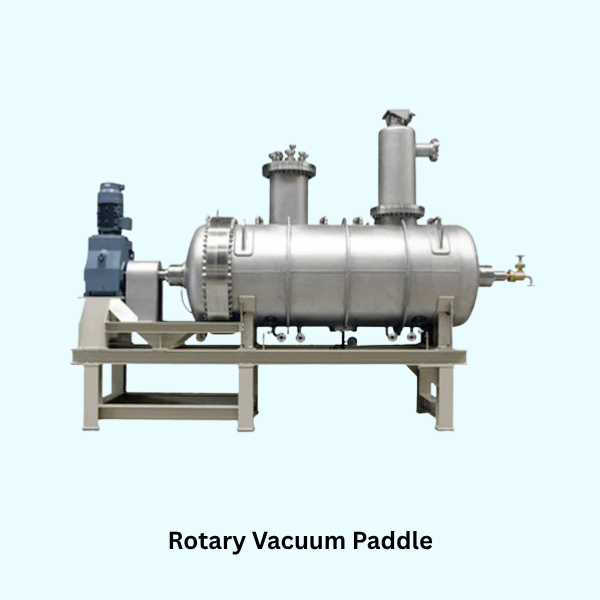

Rotary Vacuum Paddle

Rotary Vacuum Paddle

Rotary Vacuum Paddle Dryers (RVPDs) are highly efficient and robust drying systems designed for drying heat-sensitive, crystalline, granular, and pasty materials under vacuum. These dryers offer an effective and energy-saving solution for industries such as pharmaceuticals, chemicals, food, dyes, and agrochemicals, where controlled, uniform, and low-temperature drying is essential.

At Harsha Engineers India, we manufacture high-performance RVPDs built to deliver superior drying efficiency, reduced processing time, and consistent product quality. The equipment features a horizontal cylindrical vessel with a centrally mounted agitator shaft, fitted with specially designed paddles. These paddles continuously stir the material, improving heat transfer and ensuring uniform drying.

The vacuum environment lowers the boiling point of liquids, allowing drying to occur at lower temperatures—ideal for delicate or thermolabile substances. Jacketed walls provide efficient indirect heating through steam, hot water, or thermal oil. Optional features like solvent recovery systems, condensers, and CIP (Clean-in-Place) systems make RVPDs highly customizable for cleanroom and regulated production environments.

A Rotary Vacuum Paddle Dryer (RVPD) is a highly efficient drying equipment designed for drying, mixing, and processing wet materials under vacuum. It is particularly suitable for heat-sensitive, toxic, or solvent-based products, where drying at low temperatures and safe handling are essential. At Harsha Engineers, we manufacture durable, GMP-compliant Rotary Vacuum Paddle Dryers in MS, SS 304, SS 316, and special alloys, providing reliable solutions for pharmaceutical, chemical, food, and agro industries.

The principle of indirect heating and vacuum drying underpins the operation of the Rotary Vacuum Paddle Dryer:

- The wet materials are loaded into the jacketed cylindrical body of the dryer.

- The low pressure created by a vacuum pump lowers the moisture’s boiling point.

- The material is continuously agitated by rotating hollow paddles attached to a central shaft.

- Heat is transferred through the jacket and hollow paddles, ensuring uniform drying.

- Under vacuum, moisture evaporates, condenses, and is separately collected.

This process provides fast, uniform, and efficient drying while preserving product quality.

- Produced in custom grades or MS, SS 304, or SS 316.

- Body that is a jacketed cylinder and has hollow rotating paddles for maximum heat transfer.

- Construction that is vacuum-tight for safe operation.

- Continual mixing and agitation to prevent lumping of the material conforms to ASME and cGMP standards of design.

- Systems for the recovery of solvents.

- Available in a variety of capacities to meet the needs of customers.

Numerous applications for rotary vacuum paddle dryers include:

- Pharmaceutical Industry – drying of APIs, bulk drugs, intermediates, and herbal extracts.

- Dyes, pigments, resins, polymers, and fine chemicals are all dried in the chemical industry.

- Drying of starch, proteins, flavors, and food additives is a part of the food industry.

- Pesticide, fertilizer, and specialty chemical drying are examples of agrochemicals.

- Applications in the environment include the drying of waste sludge and the treatment of effluents.

- Efficient Drying: Even for tough materials, moisture is quickly removed.

- Products that are sensitive to heat can be preserved by handling them gently.

- Consistent Results: Constant mixing guarantees consistent drying.

- Energy Saving – indirect heating and vacuum operation reduce energy use.

- Safe and clean operation is ideal for solvent-based or toxic products.

- Available in a variety of capacities, materials, and configurations; customizable.

Conclusion

Rotary Vacuum Paddle Dryers from Harsha Engineers are designed for high performance, safety, and reliability in industries requiring precision drying. With their robust construction, advanced vacuum technology, and efficient mixing mechanism, our RVPDs provide an ideal solution for drying heat-sensitive, toxic, or solvent-rich products while maintaining the highest standards of safety and quality.