Shell & Tube Heat Exchangers

Shell & Tube Heat Exchangers

An autoclave is a specialized pressure vessel designed to carry out sterilization and other chemical processes requiring elevated temperature and pressure. It operates by using steam at high pressure to kill microorganisms, remove contaminants, and ensure complete sterilization of equipment, raw materials, or finished products. Autoclaves are widely used in pharmaceutical, chemical, food processing, healthcare, and research laboratories for sterilizing instruments, glassware, media, and even large-scale industrial components.

They come in different sizes and types—such as vertical, horizontal, portable, and industrial-grade—depending on the application. With safety features like pressure controls, locking systems, and temperature monitoring, autoclaves guarantee reliable, consistent, and contamination-free results. Beyond sterilization, they are also used in curing composites, vulcanizing rubber, and processing materials that require controlled heat and pressure.

Shell & Tube Products

Shell & Tube Heat Exchangers

An autoclave is a specialized pressure vessel designed to carry out sterilization and other chemical processes requiring elevated temperature and pressure. It operates by using steam at high pressure to kill microorganisms, remove contaminants, and ensure complete sterilization of equipment, raw materials, or finished products. Autoclaves are widely used in pharmaceutical, chemical, food processing, healthcare, and research laboratories for sterilizing instruments, glassware, media, and even large-scale industrial components.

They come in different sizes and types—such as vertical, horizontal, portable, and industrial-grade—depending on the application. With safety features like pressure controls, locking systems, and temperature monitoring, autoclaves guarantee reliable, consistent, and contamination-free results. Beyond sterilization, they are also used in curing composites, vulcanizing rubber, and processing materials that require controlled heat and pressure.

Single-Pass Heat Exchangers

At Harsha Engineers, we manufacture high-performance Single-Pass Heat Exchangers designed for efficient and reliable thermal transfer. In this design, the fluid flows through the tubes in a single pass from inlet to outlet, making it simple, effective, and easy to maintain.

Our single-pass exchangers are widely used in chemical plants, refineries, power generation units, pharmaceuticals, and food processing industries where moderate heat loads and steady performance are required.

Built with stainless steel, mild steel, or custom-specified alloys, each unit is precision-engineered to deliver durability, corrosion resistance, and consistent operation under demanding industrial conditions. With a focus on quality and energy efficiency, Harsha Engineers ensures every exchanger meets rigorous performance standards.

Multi-Pass Heat Exchangers

At Harsha Engineers, we design and manufacture robust Multi-Pass Heat Exchangers that provide superior heat transfer efficiency for demanding industrial applications. In this design, the fluid passes through the tube bundle multiple times, allowing greater thermal contact and improved performance compared to single-pass exchangers.

Our multi-pass heat exchangers are widely used in chemical processing, petrochemicals, power generation, refineries, food and beverage, and pharmaceutical industries, where higher heat loads and precise temperature control are essential.

Manufactured using high-grade stainless steel, mild steel, and custom alloys, these exchangers are engineered to withstand high pressures, extreme temperatures, and corrosive environments. With precision fabrication, rigorous quality checks, and long service life, Harsha Engineers ensures reliable performance and reduced operational costs.

U-Bundled Heat Exchangers

At Harsha Engineers, we specialize in manufacturing durable and efficient U-Bundled Heat Exchangers, designed for applications requiring high thermal efficiency and ease of maintenance. In this design, the tubes are bent into a U-shape, allowing the exchanger to accommodate thermal expansion without requiring additional joints or expansion fittings.

U-bundle heat exchangers are widely used in chemical industries, oil refineries, petrochemicals, pharmaceuticals, and power plants for heating, cooling, and condensing fluids. Their compact design ensures efficient heat transfer while reducing space requirements.

Built from stainless steel, mild steel, or special alloys, our exchangers are engineered to perform reliably under high pressure and temperature conditions. With a focus on quality, safety, and long service life, Harsha Engineers delivers solutions that optimize process efficiency and minimize downtime.

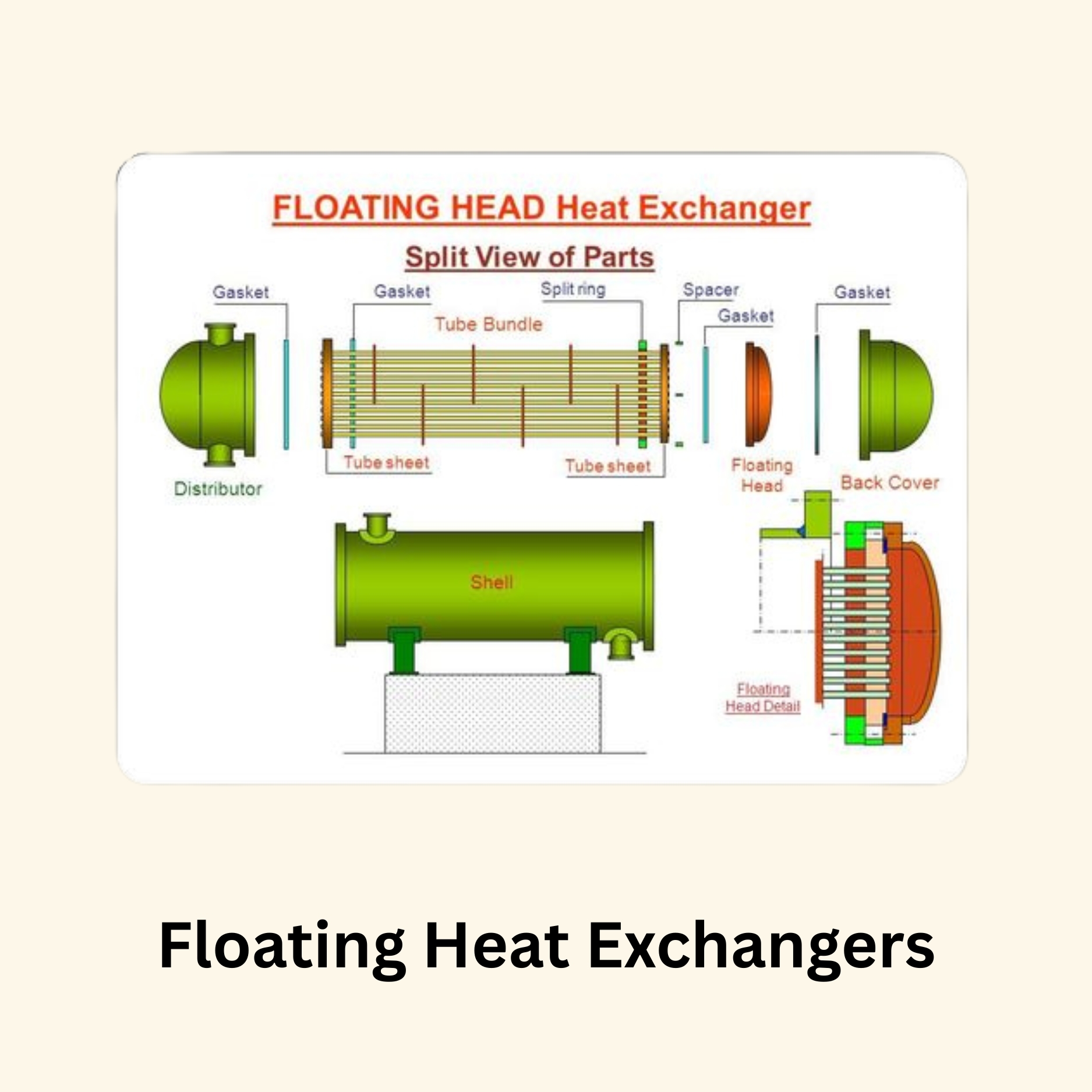

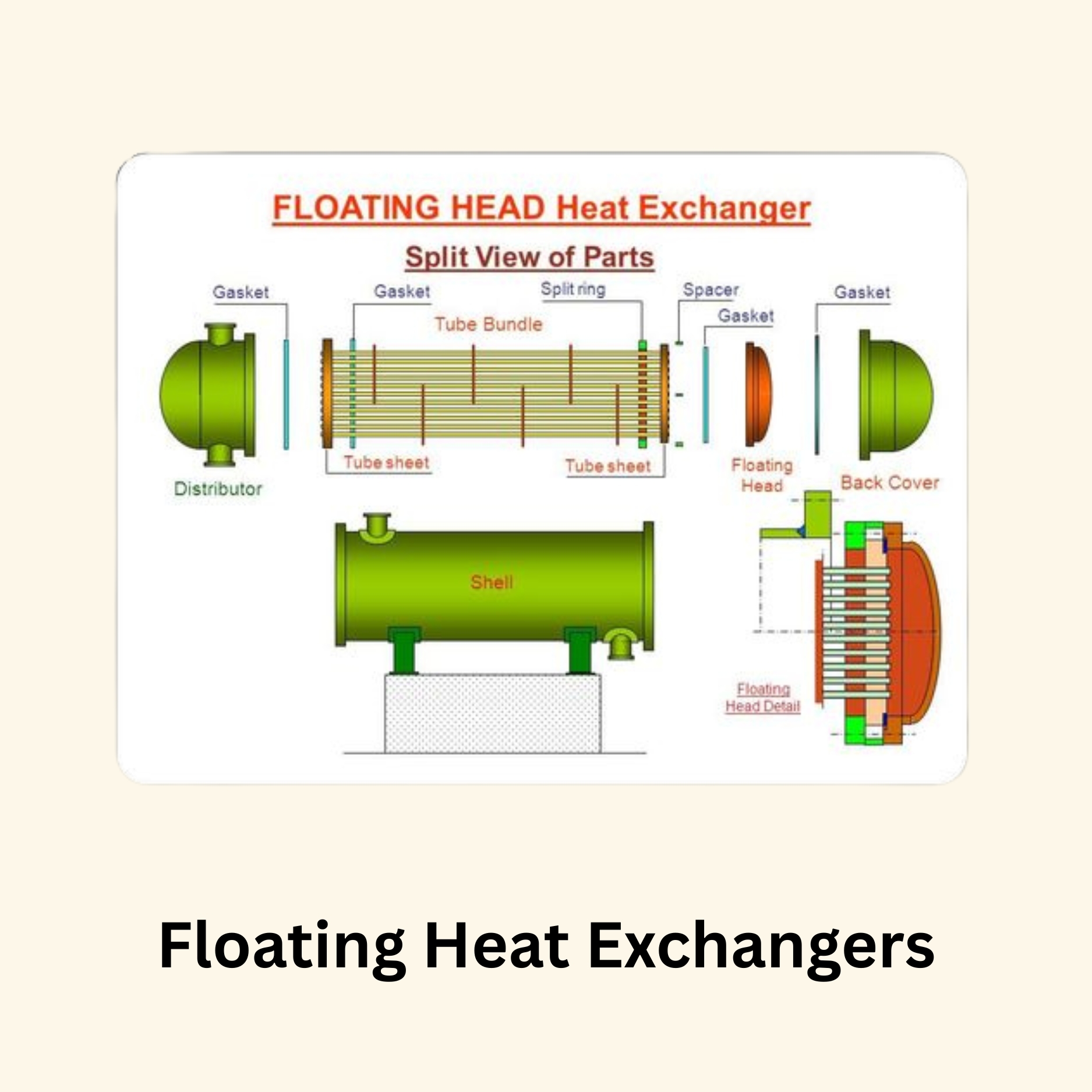

Floating Heat Exchangers

At Harsha Engineers, we manufacture high-quality Floating Head Heat Exchangers designed for maximum efficiency and flexibility in demanding industrial processes. In this design, one end of the tube bundle is fixed while the other end is allowed to “float,” enabling free expansion and contraction of tubes under varying temperature conditions.

This unique feature makes floating head exchangers ideal for high-temperature services, large temperature differences, and applications involving fouling fluids, as the tube bundle can be easily removed for cleaning and maintenance.

Widely used in refineries, chemical plants, petrochemicals, power stations, and process industries, these exchangers ensure durability, easy maintenance, and superior heat transfer performance.

Constructed from stainless steel, mild steel, or special alloys, our floating head exchangers are built to withstand extreme operating conditions while ensuring long service life and consistent output.