Wet Scrubber

Wet Scrubber

A wet scrubber is an air pollution control device that uses a liquid—usually water or a chemical solution—to remove pollutants from industrial exhaust gases. At Harsha Engineers India, we design and manufacture high-efficiency wet scrubbers that are ideal for capturing and neutralizing acidic gases, particulate matter, chemical fumes, and volatile organic compounds (VOCs). These systems work by bringing the contaminated gas stream into contact with the scrubbing liquid, where pollutants are either absorbed or chemically reacted and removed. Wet scrubbers are highly effective in applications involving corrosive gases or dust-laden emissions, making them a preferred choice in chemical processing plants, pharmaceutical industries, and metal finishing units.

Our wet scrubbers are custom-built to suit specific process requirements, ensuring optimal gas-liquid contact, efficient pollutant removal, and minimal pressure drop. At Harsha Engineers India, we focus on durability and corrosion resistance by using materials such as stainless steel, FRP (fiber-reinforced plastic), or other chemical-resistant alloys, depending on the application. We offer complete support—from system design and fabrication to installation and commissioning—ensuring that our clients receive a turnkey solution that meets both regulatory standards and operational goals for emission control.

| Parameter | Specification |

|---|---|

| Design Type | Vertical / Horizontal cylindrical tower with spray nozzles or packed bed |

| Gas Flow Capacity | 500 m³/hr to 100,000+ m³/hr (custom-built) |

| Removal Efficiency | Particulates: ≥95%; Gases (SO₂, HCl, NH₃, VOCs): 85–99% |

| Material of Construction (MOC) | PP, HDPE, PVC, FRP (Vinyl ester/Isophthalic), SS304, SS316, SS316L, Hastelloy, Titanium (on request) |

| Operating Pressure | Slight vacuum up to +0.5 bar |

| Operating Temperature | Ambient up to 150°C (depending on MOC and application) |

| Liquid-to-Gas Ratio (L/G) | 5–20 L/m³ (optimized per process) |

| Packing Media (if applicable) | PP Pall rings / Structured packing / Ceramic media |

| Mist Eliminator | Chevron vane or mesh pad (≥98% efficiency) |

| Circulation System | Recirculating pump with tank and chemical dosing system |

| Drain & Discharge | Bottom drain with blowdown valve / Overflow line |

| Cleaning Method | Manual access hatches or CIP (Clean-in-Place) option |

| Mounting Type | Skid-mounted / Baseplate / Foundation-fixed |

| Automation Options | pH/ORP controller, level sensors, PLC with HMI, auto dosing system |

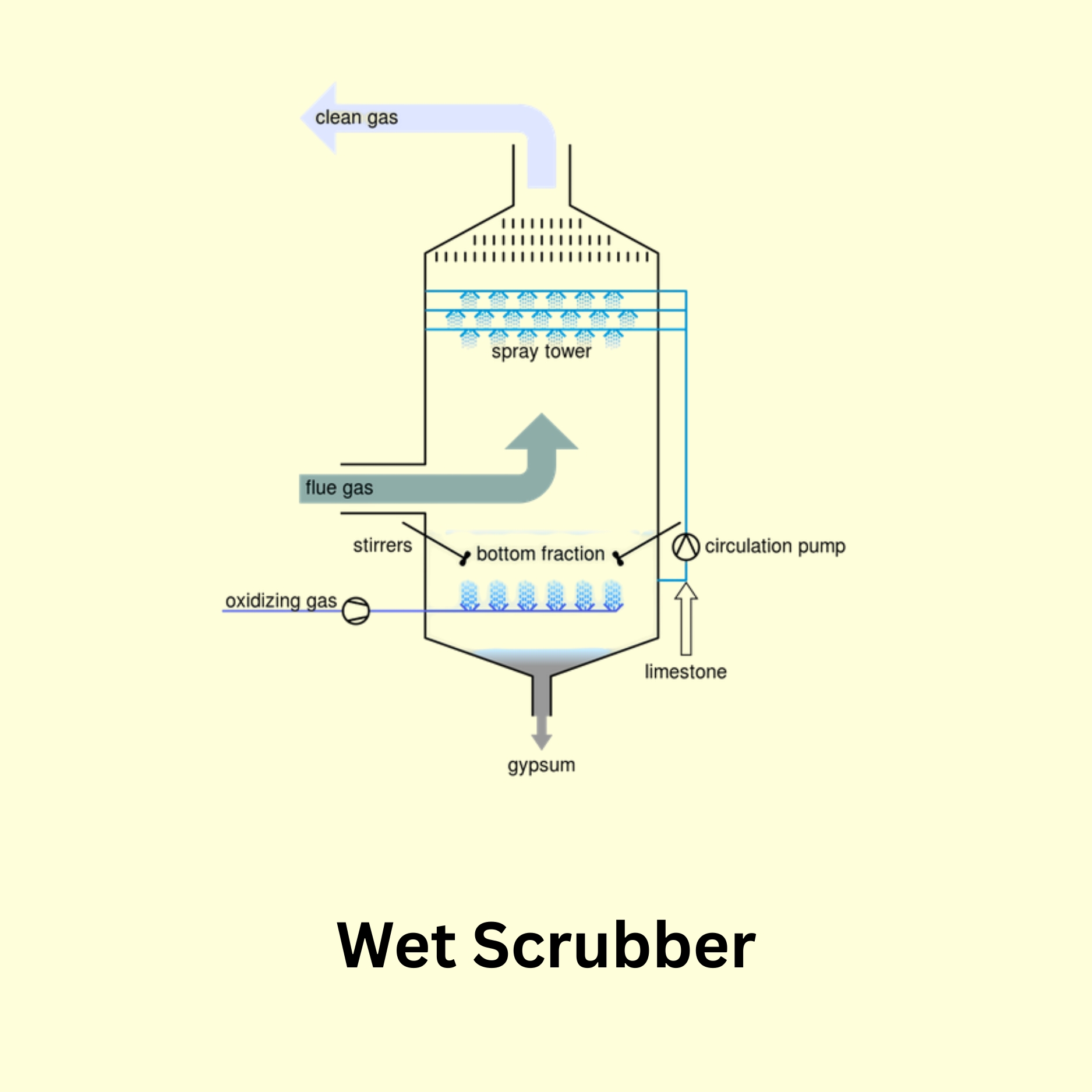

The interaction between the scrubbing liquid and the polluted gas is what makes a wet scrubber work. Fine droplets of the scrubbing liquid come into direct contact with the contaminated gas stream as it enters the scrubber. The liquid either absorbs, chemically neutralizes, or traps pollutants as particulates. After that, the cleaned gas goes out through the outlet, and the pollutant-rich liquid is taken to be treated or disposed of. Depending on the nature of the pollutants and the requirements of the application, a variety of designs, including spray towers, packed bed scrubbers, and Venturi scrubbers, are utilized.

Wet scrubbers are widely used across multiple industries, including:

- Chemical fumes and solvent vapors are removed from the pharmaceutical industry.

- Treatment of acid gases (HCl, SO2, Cl2, NH3, etc.) in chemical plants Food & Beverage Industry – Odor and vapor control

- Control of dust, nitrogen oxides, and sulfur dioxide (SO2) emissions from power plants and petrochemicals Metals & Mining Industry – Capture of fumes, dust, and toxic vapors

- High efficiency in removing both gaseous and particulate pollutants

- Effective cooling of hot gas streams before release

- Able to safely handle gases that are explosive, flammable, or corrosive

- Dual function – pollutant removal and dust suppression in a single system

- Eco-friendly and ensures compliance with emission norms

- Design that can be changed to meet specific industrial needs

Conclusion

Harsha Engineers is an industry leader in the design and production of high-performance Wet Scrubbers that are efficient, dependable, and durable. Our systems are designed to be low-maintenance and cost-effective to operate while also adhering to stringent environmental regulations. Whether for pharmaceuticals, chemicals, food processing, or heavy industries, our Wet Scrubbers ensure cleaner emissions, safer workplaces, and a sustainable future.